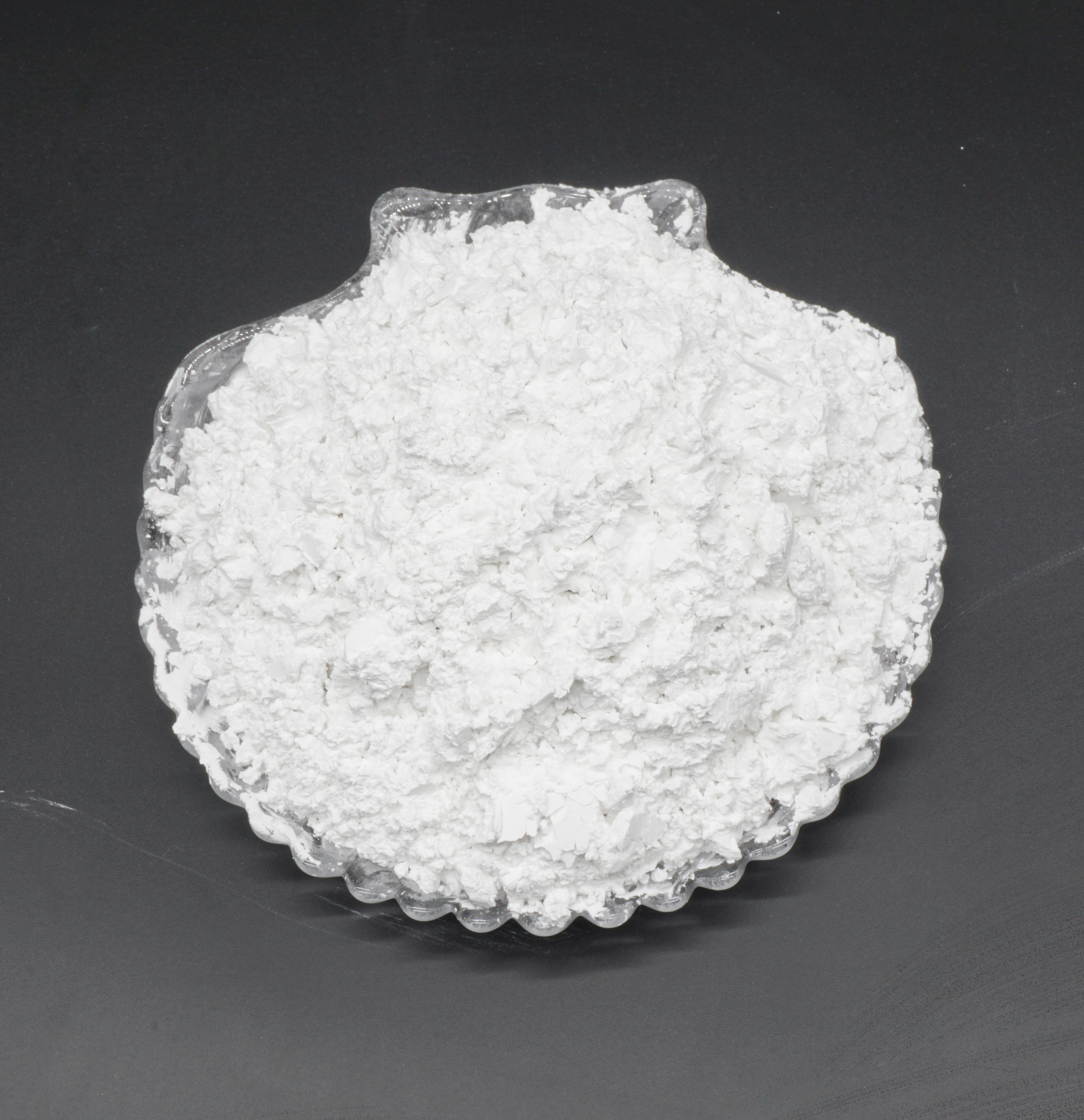

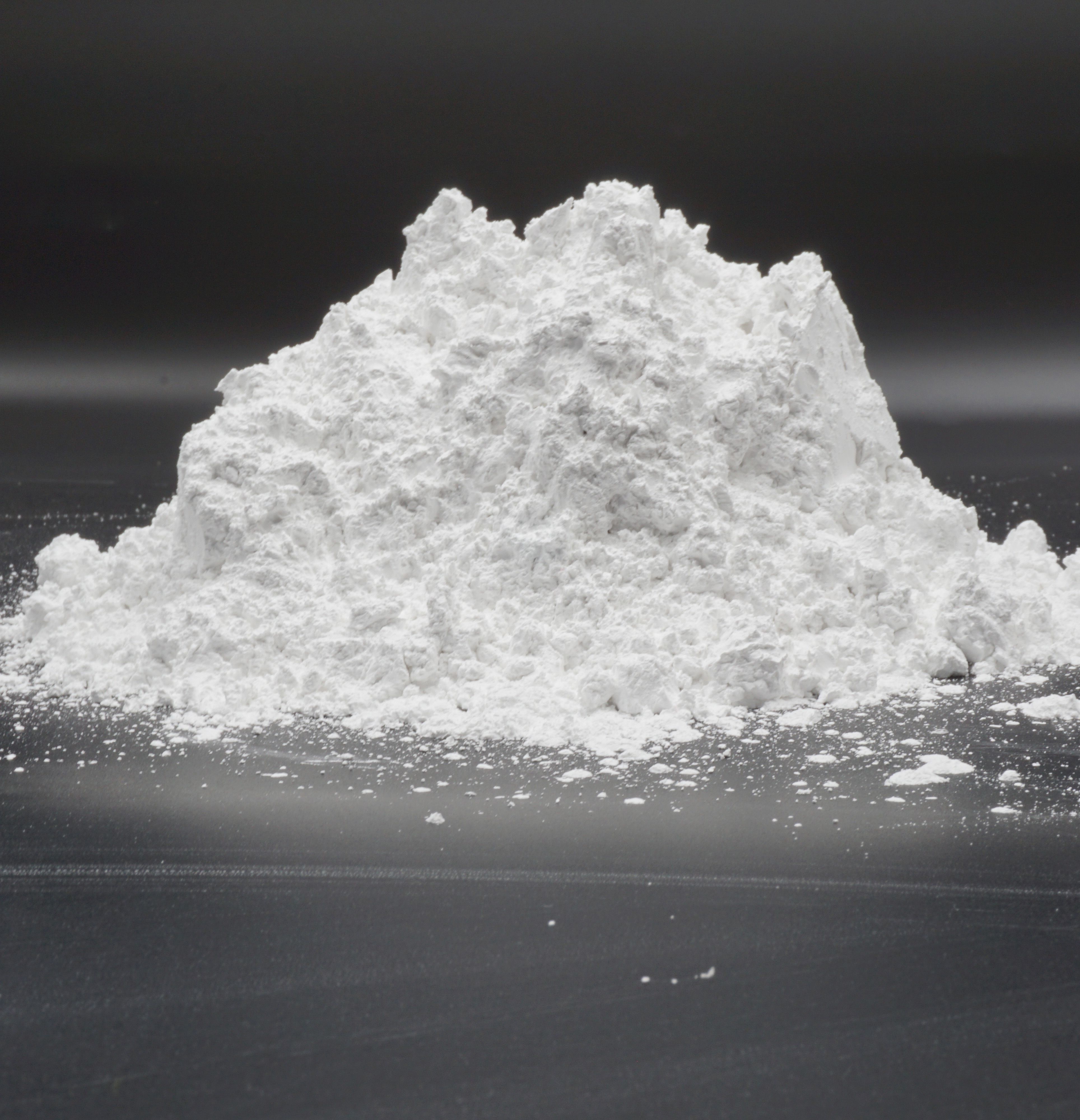

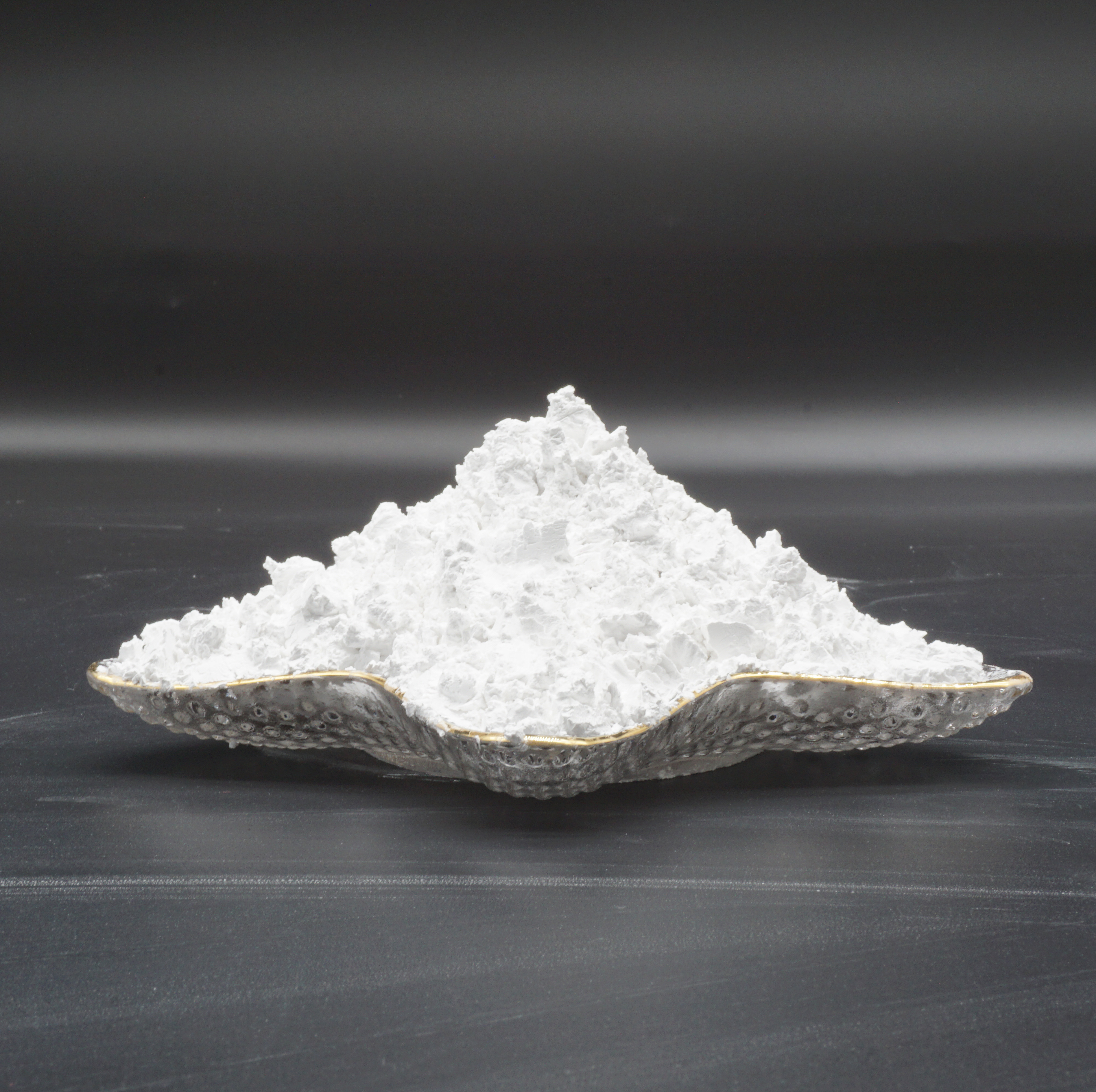

Lihlahisoa

Mecha ea phatlalatso ea ho sila 240#-12500# Alumina Powder e tšoeu e Fuselitsoeng

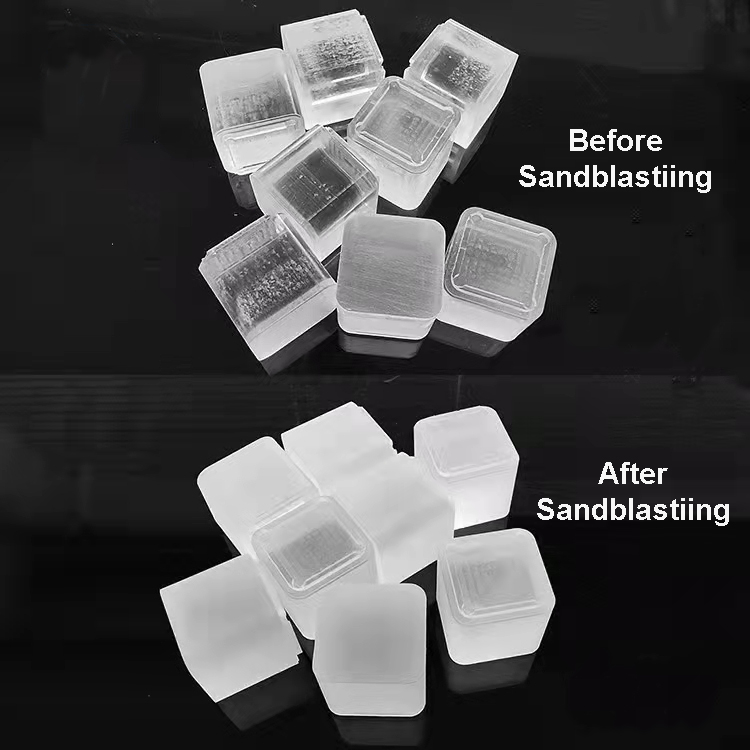

Tlhaloso ea WFA

Corundum e tšoeu e nang le phofo ea alumina ea indasteri e le lisebelisoa tse tala, ka har'a arc ka mor'a likhato tse 2000 tsa mocheso o phahameng o qhibiliha ka mor'a ho pholile, ho sila le ho bōptjoa, karohano ea matla a khoheli ho tlosa tšepe, skrine ka mefuta e fapaneng ea granularity, sebopeho sa eona se teteaneng, boima bo phahameng, likaroloana Angle e bohale, e loketseng ho etsoa ha ceramics, resin consolidation abrasive tools and grinding, polishing, sandblasting, precision casting (investment casting special corundum), joalo-joalo E ka boela ea sebelisoa ho etsa thepa ea boemo bo phahameng ea refractory

Sebopeho sa Lik'hemik'hale le 'Mele

| MOHLALA: 240#,280#,320#,360#,400#,500#,600#,700#,800#,1000#,1200#,1500#,2000#,2500#,3000#,4000#,6 0 0 0 #,8 0 0 0 #,1 0 0 0 0 #,12500# | |||

| chamical analysis(%) | thepa ya mmele | ||

| Al2O3 | ≥99.2 | mmala | tšoeu |

| SiO2 | ≤0.04 | sebopeho sa kristale | a-Al2O3 |

| NaO2 | ≤0.22 | bongata bo boholo | 1.75-1.95g/cm3 |

| Fe2O3 | ≤0.04 | mokoloko oa 'nete | 3.95-3.97g/cm3 |

| K2O | ≤0.01 | boima ba mosh | 9.0 mets |

| tshebediso | ho bentša, ho qhomisa, ho roala, ho sila, joalo-joalo. | ||

Tšebeliso ea WFA

1. Etsa li-ceramics tse pepeneneng: mabone a sodium a khatello e phahameng, fensetere ea EP-ROM.

Αlpha-Al2O3 e ka sintered ka ceramic e bonaletsang ho e sebelisa e le lisebelisoa tsa lebone la sodium le khatello e phahameng;hammoho le e ka sebelisoa e le lebone la compact fluorescent lera le sireletsang la phosphor lera ho ntlafatsa bophelo ba lebone.

2. E le lisebelisoa tse phahameng tsa ho bentša bakeng sa: khalase, tšepe, lisebelisoa tsa semiconductor, polasetiki, tepi, lebanta la ho sila, joalo-joalo.

3. E le tlatsetso: tiisa pente, rabara, polasetiki e sa keneng.

E le thepa e ncha e kopantsoeng, phofo ea Al2o3 e ka sebelisoa e le ho matlafatsa ho hasana le li-additives, tse kang ho eketsa alumina nanoparticles ka rabara, ho hanyetsa ho apara ho ka ntlafatsoa ka makhetlo a 'maloa.

4. Sebelisa e le catalyst, catalyst carrier, analytical reagent.

Ka lebaka la thepa ea eona e khethehileng, phofo ea Al2o3 e sebelisoa haholo e le mohloli le mojari oa eona, ka lirafshoa le masimo a mang.

5. Sebelisa bakeng sa ho roala

Alumina nanoparticles e le sesebelisoa sa optical le lera le sireletsang holim'a thepa e ka monya leseli la ultraviolet, 'me ka har'a maqhubu a mang a khanya e ka hlahisoang ka boholo ba karoloana ea bolelele ba khanya.

6.Sebelisa bakeng sa ceramic matla a Phahameng

Lits'ebetsong tsa ceramic, li-ceramics tse nepahetseng tse entsoeng ke nano alumina phofo li na le polasetiki ea tšepe e ts'oanang le ho tiea, boima bo bobebe, haholoholo, bo matlafatsa matla haholo.

Ka ho eketsa palo e nyane ea nano-alumina ka har'a matrix a tloaelehileng a ceramic ho ka etsa hore thepa ea mochini oa thepa e imenne habeli ho ntlafatsa ho tiea ha li-ceramics ho fokotsa mocheso oa eona oa sintering.

- E sebelisoa bakeng sa ho sila mahala, joalo ka indasteri ea likhalase.

2. E sebelisoa bakeng sa lihlahisoa tsa likhohlano le mekato e sa senyeheng.

3. E loketse bakeng sa resin kapa ceramic bond abrasive, joalo ka lebili la ho sila, ho khaola lebili la ho sila, joalo-joalo.

4. E loketse bakeng sa lihlahisoa tse hanyetsang, tse apereng le tse hanyetsang.

5. E sebelisetsoa ho polishing, joalo ka grindstone, grinding block, plate turning, joalo-joalo.

6. E sebelisetsoa ho roala lisebelisoa tsa abrasive, tse kang sandpaper, lesela la emery, lebanta la lehlabathe, joalo-joalo.

7. E sebelisetsoa ho lahla ka mokhoa o nepahetseng, ho sila, ho sila, ho hlahisa hlobo ea ho bentša.

Potso ea hau

Haeba u na le lipotso.Ka kopo ikutloe u lokolohile ho ikopanya le rona.