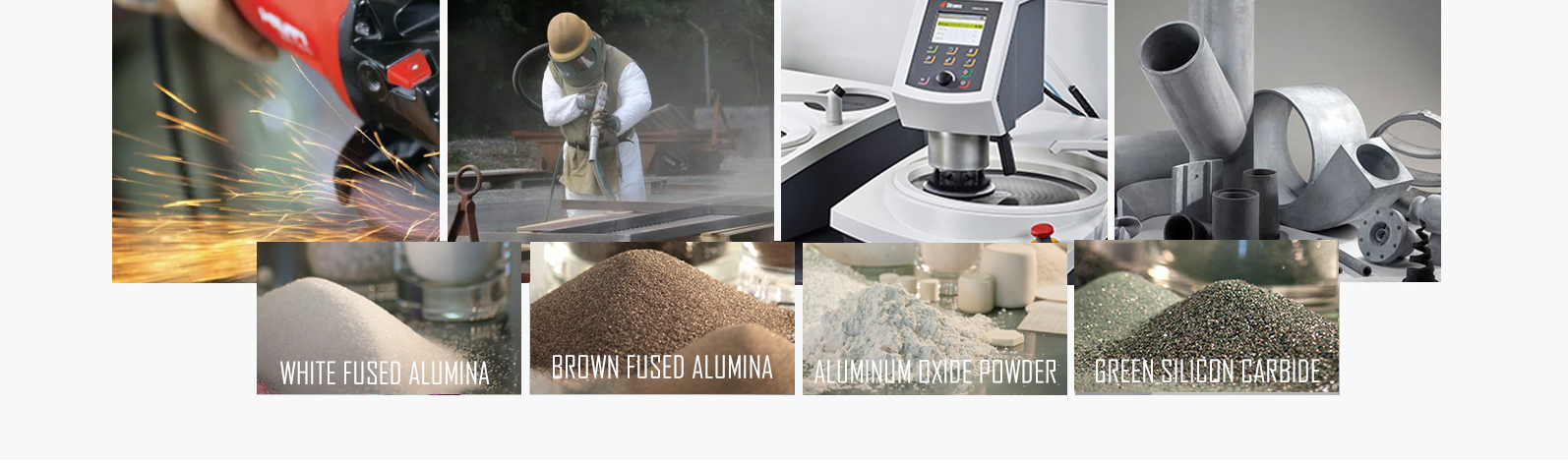

Lihlahisoa

F12-F220 White Fused Alumina Oxide Grits

Alumina e tšoeu e kopantsoeng

Alumina e tšoeu e kopantsoeng e entsoe ka phofo ea alumina e tlaase-sodium e hloekileng ka ho qhibiliha mocheso o phahameng, kristale e pholileng, ebe e senya.Alumina grit e tšoeu e kopantsoeng e tlas'a taolo e thata ho boloka kabo ea boholo ba lijo-thollo le chebahalo e tsitsitseng.

Whiet Fused Alumina Properties

E tšoeu, α kristale e fetang 99%, bohloeki bo phahameng, boima bo phahameng, le boima bo phahameng, matla a matla a ho itšeha, botsitso bo matla ba lik'hemik'hale, le ho kenya letsoho ka matla.

| Mohs boima | 9 |

| Boima ba bongata | 1.75-1.95g/cm3 |

| Matla a khoheli a khethehileng | 3.95g/cm3 |

| Boima ba molumo | 3.6 |

| Tekanyo ea ho qhibiliha | 2250 ℃ |

| Refractory degree | 2000 ℃ |

| E sebelisoa bakeng sa refractory, castable | |||||

| Thepa | 0-1 1-3 3-5m/m | F100 F200 F325 | |||

| Boleng ba Tiisetso | Boleng bo Tlwaelehileng | Boleng ba Tiisetso | Boleng bo Tlwaelehileng | ||

| Sebopeho sa Lik'hemik'hale | Al2O3 | ≥99.1 | 99.5 | ≥98.5 | 99 |

| SiO2 | ≤0.4 | 0.06 | ≤0.30 | 0.08 | |

| Fe2O3 | ≤0.2 | 0.04 | ≤0.20 | 0.1 | |

| Na2O | ≤0.4 | 0.3 | ≤0.40 | 0.35 | |

| E sebelisoa bakeng sa li-abrasives, ho phatloha, ho sila | |||

| Thepa | Lijo-thollo | ||

| 8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220# | |||

| Boleng ba Tiisetso | Boleng bo Tlwaelehileng | ||

| Sebopeho sa Lik'hemik'hale | Al2O3 | ≥99.1 | 99.5 |

| SiO2 | ≤0.2 | 0.04 | |

| Fe2O3 | ≤0.2 | 0.03 | |

| Na2O | ≤0.30 | 0.2 | |

| E sebelisoa bakeng sa abrasives, lapping, polishing | ||||

| Thepa | Micropowder | |||

| "W" | W63 W50 W40 W28 W20 W14 W10 W7 W5 W3.5 W2.5 W1.5 W0.5 | |||

| "FEPA" | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000 | |||

| "JIS" | 240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000#000#1050# 1020 | |||

| Boleng ba Tiisetso | Boleng bo Tlwaelehileng | |||

| Sebopeho sa Lik'hemik'hale | Al2O3 | ≥99.1 | 99.3 | |

| SiO2 | ≤0.4 | 0.08 | ||

| Fe2O3 | ≤0.2 | 0.03 | ||

| Na2O | ≤0.4 | 0.25 | ||

1.Ho qhomisa lehlabathe, ho bentša le ho sila tšepe le khalase.

2. Ho tlatsa pente, lesela le sa senyeheng, ceramic le glaze.

3.Ho etsa lejoe la oli, lejoe la ho sila, lebili la ho sila, sandpaper le lesela la emery.

4.Ho hlahisa li-membrane tsa li-filter tsa ceramic, li-tubes tsa ceramic, lipoleiti tsa ceramic.

5.Tlhahiso ea mokelikeli o benyang, boka bo tiileng le boka ba metsi.

6.Bakeng sa tšebeliso ea fatše e manganga.

7.Ho sila le ho penta ho tsoetseng pele ha likristale tsa piezoelectric, semiconductors, tšepe e sa hloekang, aluminium le lisebelisoa tse ling le tse seng tsa tšepe.

8.Tlhaloso le tlhamo

Potso ea hau

Haeba u na le lipotso.Ka kopo ikutloe u lokolohile ho ikopanya le rona.