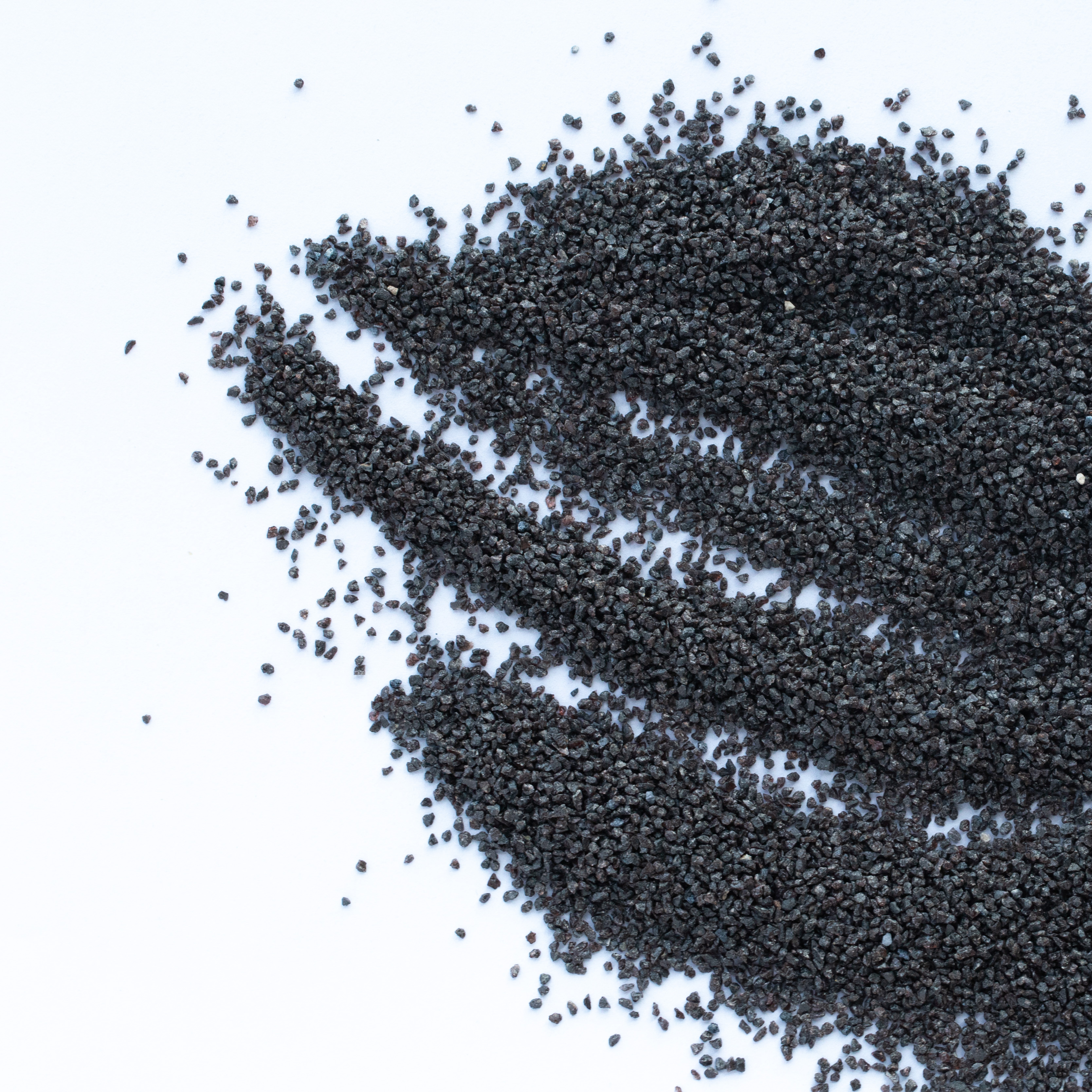

Lihlahisoa

grit e sootho e entsoeng ka alumina bakeng sa lebili le silang la sandpaper le tlositsoeng ka abrasive

Brown fused alumina / Brown corundum, eo hangata e tsejoang e le emery, ke corundum ea maiketsetso e sootho e entsoeng ka ho qhibiliha le ho fokotsa lisebelisoa tse tharo tse tala: bauxite, carbon material le li-filings tsa tšepe ka sebōping sa motlakase sa arc, ka hona lebitso.Karolo ea eona e ka sehloohong ke alumina, 'me limaraka li boetse li khetholloa ke litaba tsa aluminium.Ha aluminium e le tlase, boima bo tlase.Boholo ba karoloana ea sehlahisoa bo hlahisoa ho latela maemo a machaba le maemo a naha, 'me bo ka sebetsoa ho latela litlhoko tsa mosebelisi.Kakaretso ea likaroloana ke F4 ~ F320, 'me sebopeho sa eona sa lik'hemik'hale se fapana ho latela boholo ba karoloana.Ntho e ikhethang ke hore boholo ba kristale bo nyane ebile ha bo na tšusumetso.Kaha e sebetsoa le ho rojoa ke mochine o itšilang, boholo ba likaroloana ke likaroloana tse chitja.Bokaholimo bo omme ebile bo hloekile, 'me ho bonolo ho ikopanya le se tlamang.Brown fused alumina e entsoe ka abrasive grade bauxite e le thepa e tala 'me e tlatselletsoa ka lisebelisoa tse thusang.E hloekisitsoe ka sebōping sa motlakase sa arc mocheso o phahameng ka holimo ho 2250 ℃.Motheong ona, e hloekisoa ke karohano e matla ea matla a khoheli mme ho hanyetsa ha eona ho kaholimo ho 1850 ℃.Corundum e sootho e hlahisoang ke k'hamphani ea rona e na le litšobotsi tsa bohloeki bo phahameng, crystallization e ntle, metsi a matla, coefficient e tlaase ea ho atolosa le ho hanyetsa kutu.Sehlahisoa se na le litšobotsi tsa ho se phatlohe, ho se phophole, le ho se phunye nakong ea ts'ebetso ea kopo, 'me hangata se sebelisoa liindastering tsa li-abrasives le tsa refractory.

| Kopo | Tlhaloso | Motsoako oa mantlha oa lik'hemik'hale% | Ntho ea Magnetic% | ||||

| Al2o3 | Fe2o3 | Sio2 | Tio2 | ||||

| Li-abrasives | F | 4#-80# | ≥95 | ≤0.3 | ≤1.5 | ≤3.0 | ≤0.05 |

| 90#—150# | ≥94 | ≤0.03 | |||||

| 180#—240# | ≥93 | ≤0.3 | ≤1.5 | ≤3.5 | ≤0.02 | ||

| P | 8#—80# | ≥95.0 | ≤0.2 | ≤1.2 | ≤3.0 | ≤0.05 | |

| 100#—150# | ≥94.0 | ≤0.3 | ≤1.5 | ≤3.5 | ≤0.03 | ||

| 180#—220# | ≥93.0 | ≤0.5 | ≤1.8 | ≤4.0 | ≤0.02 | ||

| W | 1#-63# | ≥92.5 | ≤0.3 | ≤1.5 | ≤3.0 | -------- | |

| Refractory | Duansha | 0-1 limilimithara 1-3 limilimithara 3-5 limilimithara 5-8mm 8-12 limilimithara | ≥95 | ≤0.3 | ≤1.5 | ≤3.0 | -------- |

| 25-0 limilimithara 10-0mm 50-0mm 30-0mm | ≥95 | ≤0.3 | ≤1.5 | ≤3.0 | -------- | ||

| Phofo | 180#-0 200#-0 320#-0 | ≥94.5 ≥93.5 | ≤0.5 | ≤1.5 | ≤3.5 | -------- | |

Lisebelisoa tsa li-abrasives: Lebili la ho sila, lebanta la abrasive, sandpaper, lesela la abrasive, sengoathoana se sehang, theknoloji ea ho qhomisa lehlabathe, ho sila, fatše, ho seha ha sefofane sa metsi, li-abrasives tse koahetsoeng, li-abrasives tse kopantsoeng, joalo-joalo.

Lisebelisoa tsa Refractory: Setene se ka hasoang, se refractory, lisebelisoa tsa ramming, poleiti ea li-slide, nozzle, ladle, lisebelisoa tsa lesela.ho etsa lintho ka nepo, joalo-joalo

Brown corundum e bitsoa meno a indasteri: a sebelisoa haholo ho li-refractories, mabili a sila, le sandblasting.

1. E sebelisetsoa ho etsa lisebelisoa tse tsoetseng pele tsa refractory, li-castable, litene tse refractory, joalo-joalo.

2. Sandblasting-the abrasive e na le boima bo itekanetseng, boima bo bongata bo phahameng, ha e na silika e sa lefelloeng, matla a khoheli a phahameng, le ho tiea ho hotle.Ke sesebelisoa se loketseng sa "setsoalle sa tikoloho" sa lehlabathe.E sebelisoa haholo ho profilse ea aluminium, profilse ea koporo, likhalase le li-jean tse hlatsoitsoeng.Precision hlobo le masimo a mang;

3. Ho sila-ho sila mahala, ho sebelisoa ho sila mahala masimong a tube ea litšoantšo, khalase ea optical, silicon ea monocrystalline, lense, khalase ea ho shebella, khalase ea kristale, jade, joalo-joalo Ke lisebelisoa tsa ho sila tsa boemo bo holimo tse sebelisoang haholo Chaena. ;

4. Resin Abrasives-Abrasives e nang le 'mala o loketseng, boima bo botle, boima, mofuta o loketseng oa likaroloana le ho boloka moeli, o sebelisoang ho li-abrasives tsa resin, phello e ntle;

5. Li-abrasives tse koahetsoeng-li-abrasives ke lisebelisoa tse tala bakeng sa bahlahisi ba kang sandpaper le gauze;

6. Filler e sebetsang-haholo-holo e sebelisetsoang likarolo tsa brake tsa likoloi, lithaere tse khethehileng, lihlahisoa tse khethehileng tsa kaho le li-collar tse ling, tse ka sebelisoang e le lisebelisoa tse sa senyeheng tse kang litsela tsa lifofane, li-docks, libaka tsa ho paka makoloi, mekato ea indasteri, libaka tsa lipapali, joalo-joalo;

7. Sefa mecha ea litaba-sebaka se secha sa ts'ebeliso ea li-abrasives.Li-abrasives tsa granular li sebelisoa e le mecha ea litaba e ka tlaase ea bethe ea ho hloekisa ho hloekisa metsi a nooang kapa metsi a litšila.Ke mofuta o mocha oa thepa ea ho hloekisa metsi lapeng le kantle ho naha, haholo-holo e loketseng ts'ebetso ea liminerale tsa tšepe tse se nang ferrous: mochini oa boima ba ho cheka seretse sa oli :

8. Hydraulic cutting-sebelisa li-abrasives e le mokhoa oa ho itšeha 'me o itšetlehile ka li-jet tsa metsi tse nang le khatello e phahameng bakeng sa ho itšeha ha motheo.E sebelisoa ho seha liphaephe tsa oli (khase ea tlhaho), tšepe le likarolo tse ling.Ke mokhoa o mocha, o baballang tikoloho le mokhoa o bolokehileng oa ho itšeha.

Potso ea hau

Haeba u na le lipotso.Ka kopo ikutloe u lokolohile ho ikopanya le rona.