Lihlahisoa

Aluminium Oxide e Pholisetsang Phofo ea Aluminium Oxide

Kenyelletso ea Aluminium oxide phofo

Aluminium oxide phofo, e tsejoang hape e le alumina, ke phofo e tšoeu e ntle e nang le likaroloana tsa aluminium oxide (Al2O3).E sebelisoa hangata liindastering tse 'maloa ka lebaka la thepa ea eona e fapaneng le lits'ebetso.

Melemo ea Phofo ea Aluminium Oxide

- Boima bo phahameng le ho se mamele

- Sebaka se Phahameng sa Melting

- Boikemisetso ba Lik'hemik'hale

- Insulation ea Motlakase

- Biocompatibility

- Khanyetso ea Corrosion

- Sebaka se Phahameng se Phahameng

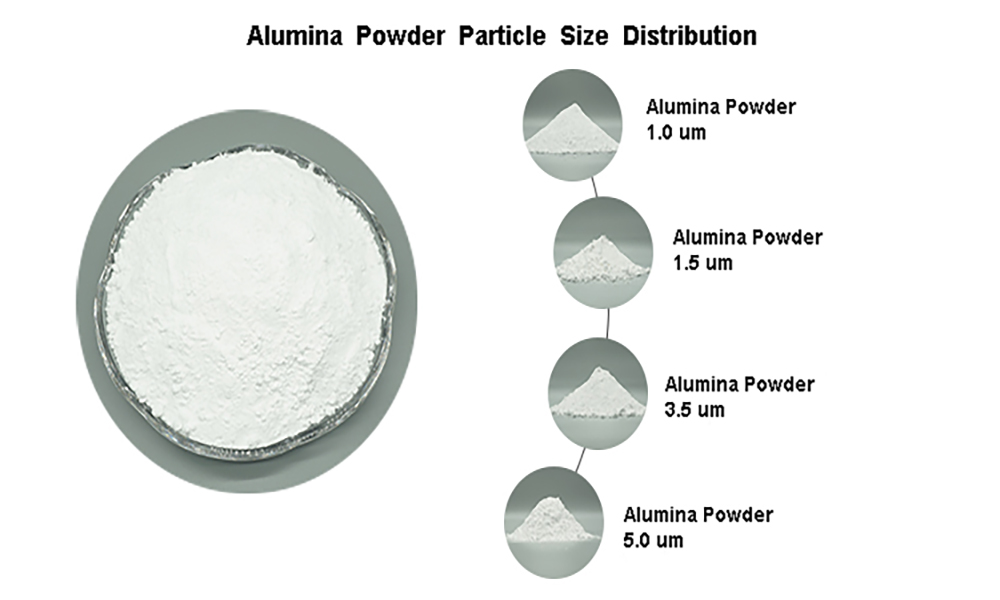

| Tlhaloso | AI203 | Na20 | D10(um)

| D50(um)

| D90(um)

| Likaroloana tsa kristale tsa mantlha | sebaka se itseng sa bokahodimo(m2/g) |

| 12500# | =99.6 | ≤002 | >0.3 | 0.7-1 | <6 | 0.3 | 2—6 |

| 10000# | >99.6 | ≤0.02 | >0.5 | 1-1.8 | <10 | 0.3 | 4—7 |

| 8000# | >99.6 | ≤0.02 | >0.8 | 2.0-3.0 | <17 | 0.5 | <20 |

| 6000# | >99.6 | 0.02 | >0.8 | 3.0-3.5 | <25 | 0.8 | <20 |

| 5000# | >99.6 | 0.02 | >0.8 | 4.0-4.5 | <30 | 0.8 | <20 |

| 4000# | >99.6 | <0.02 | >0.8 | 5.0-6.0 | <35 | 1.0-1.2 | <30 |

1.Indasteri ea Ceramic:Alumina phofo e sebelisoa haholo e le thepa e tala bakeng sa ho etsa lirafshoa, ho kenyeletsoa lirafshoa tsa elektronike, lirafshoa tsa refractory, le lirafshoa tse tsoetseng pele tsa theknoloji.

2.Indasteri ea ho Pholisetsa le ho Abrasive:Alumina phofo e sebelisoa e le sesebelisoa sa ho bentša le ho senya lits'ebetsong tse fapaneng tse kang lilense tsa optical, semiconductor wafers, le bokaholimo ba tšepe.

3.Catalysis:Alumina phofo e sebelisoa e le ts'ehetso ea ts'ehetso indastering ea petrochemical ho ntlafatsa katleho ea li-catalysts tse sebelisoang ts'ebetsong ea ho hloekisa.

4.Thermal Spray Coatings:Alumina phofo e sebelisoa e le thepa ea ho roala ho fana ka kutu le ho itoanela libakeng tse fapaneng tsa indasteri ea lifofane le tsa likoloi.

5.Insulation ea Motlakase:Alumina phofo e sebelisoa e le thepa ea ho kenya motlakase lisebelisoa tsa elektroniki ka lebaka la matla a eona a phahameng a dielectric.

6.Indasteri ea Refractory:Alumina phofo e sebelisoa e le thepa e hanyetsang lits'ebetsong tse phahameng tsa mocheso, tse kang li-linnings tsa sebōpi, ka lebaka la sebaka se phahameng sa ho qhibiliha le botsitso bo botle ba mocheso.

7.Kenyelletso ka Polymers:Alumina phofo e ka sebelisoa e le tlatsetso ho li-polymers ho ntlafatsa thepa ea bona ea mochini le ea mocheso.

Potso ea hau

Haeba u na le lipotso.Ka kopo ikutloe u lokolohile ho ikopanya le rona.