Lihlahisoa

Ho pola le ho Sila Phofo ea Aluminium Oxide ea Micropowder bakeng sa Sintering Corundum le Ceramics

Tlhaloso ea Phofo ea Aluminium Oxide

Alumina phofoke ntho e hloekileng haholo, e entsoeng ka bokhabanealuminium oxide (Al2O3)e sebelisoang haholo lits'ebetsong tse fapaneng tsa indasteri.Ke phofo e tšoeu ea kristale eo hangata e hlahisoang ka ho hloekisoa ha ore ea bauxite.

Tlhaloso ea Aluminium Oxide Powder

| Thepa ea Sebele: | |

| Mmala | Bosoeu |

| Ponahalo | Phofo |

| Mohs boima | 9.0-9.5 |

| Sebaka se qhibilihang (ºC) | 2050 |

| Sebaka se belang (ºC) | 2977 |

| Boima ba nnete | 3.97g/cm3 |

| Tlhaloso | Al2O3 | Na2O | D50(um) | Likaroloana tsa pele tsa kristale | Boima ba Bongata |

| 0.7 hle | ≥99.6 | ≤0.02 | 0.7-1.0 | 0.3 | 2-6 |

| 1.5 um | ≥99.6 | ≤0.02 | 1.0-1.8 | 0.3 | 4-7 |

| 2.0 um | ≥99.6 | ≤0.02 | 2.0-3.0 | 0.5 | <20 |

Aluminium oxide powder (Al2O3) ke sesebelisoa se feto-fetohang se fumanang lits'ebetso tse ngata ho pholletsa le liindasteri tse fapaneng.

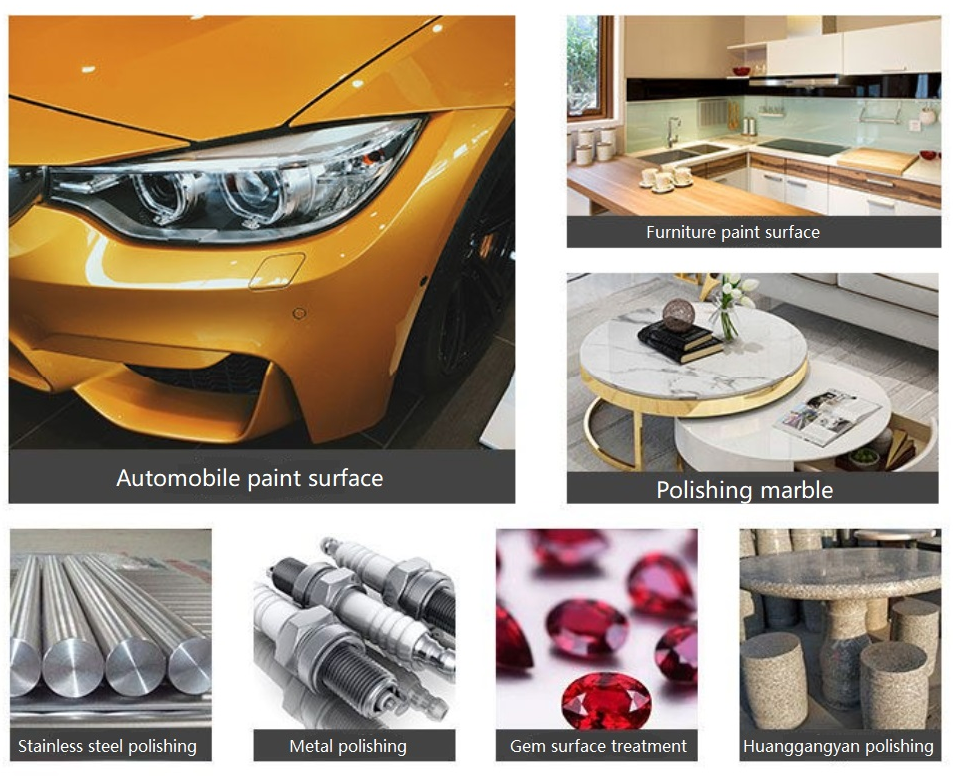

- Li-abrasives: mabili a silang, sandpaper, metsoako ea ho bentša, le mecha ea phatlalatso e qhomisang ka mahlaba

- Refractories: libopi tsa masela, libono le lisebelisoa tse ling tsa mocheso o phahameng

- Liaparo: ho fafatsa ka mocheso kapa ho beha mouoane oa lik'hemik'hale ho etsa liphahlo tse sireletsang

- Li-Catalysts: liindasteri tsa petrochemical, tsa meriana le tsa lik'hemik'hale

- Insulation ea Motlakase: liboto tsa potoloho, li-insulators, le lisebelisoa tse sireletsang matla a phahameng

- Li-ceramics: li-substrates tsa ceramic, lisebelisoa tsa elektroniki, lisebelisoa tsa ho itšeha, le likarolo tse sa senyeheng.

- Additive Manufacturing: selective laser sintering (SLS) kapa binder jetting

- Li-fillers le li-pigments

Potso ea hau

Haeba u na le lipotso.Ka kopo ikutloe u lokolohile ho ikopanya le rona.

foromo ea ho botsa

Ngola molaetsa wa hao mona mme o re romele wona