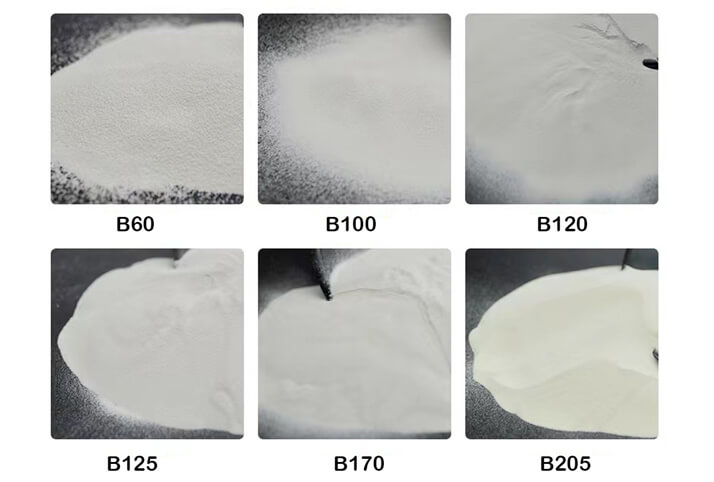

Lehlabathe la ceramic le fumaneng tlhokomelo e kholo lilemong tsa morao tjena ke lifaha tsa zirconium oxide (sebopeho: ZrO₂56% -70%, SIO₂23% -25%), e leng selikalikoe, bokaholimo bo boreleli ntle le ho senya sesebediswa sa mosebetsi, boima bo phahameng, elasticity e ntle le rebound e mengata ea lehlabathe nakong ea ho phatloha ha lehlabathe, e leng se loketseng lisebelisoa tse rarahaneng (tšepe, polasetiki).

1.Likotoana tse entsoeng ka majoe le tse entsoeng ka holim'a metsi, phekolo ea mocheso ka mor'a ho hloekisa le ho bentša sesebediswa sa mosebetsi

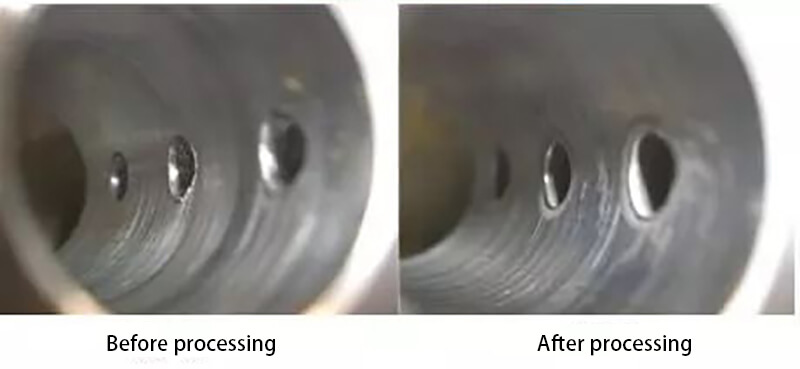

①sandblasting ka hloekisa litšila tsohle holim'a workpiece ka mor'a ho lahla le forging, tjheseletsa le mocheso kalafo (jwalo ka oxidation, oli le masala a mang), le bentsa bokaholimo ba workpiece ho ntlafatsa qetello ea workpiece le ho bapala seabo sa ho kgabisa sesebedisoa.

②Ho hloekisa lehlabathe ho ka etsa hore mosebetsi oa ho sebetsa o senole junifomo le 'mala o tsitsitseng oa tšepe, e le hore ponahalo ea mosebetsi o motle haholo, e khabise karolo ea mokhabiso.

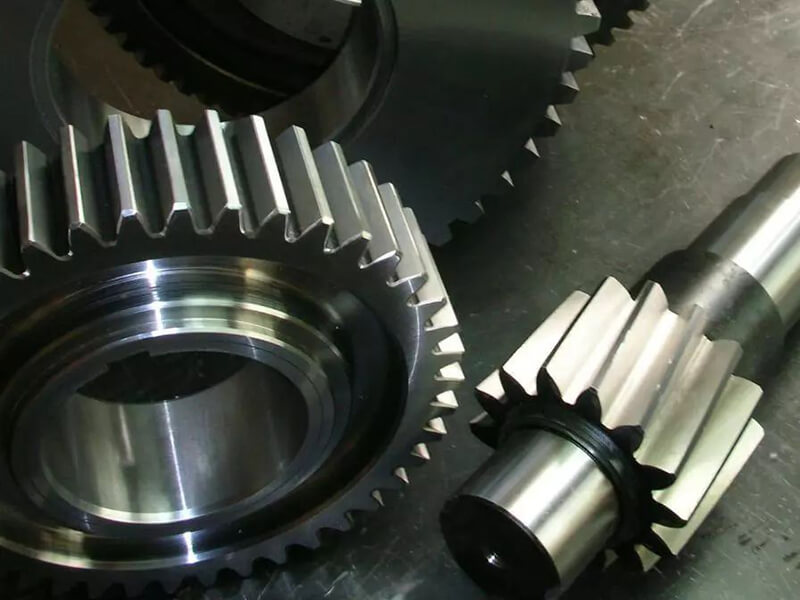

2.Ho hloekisa likarolo tse entsoeng ka mochini le ho khabisa bokaholimo

Sandblasting e ka hloekisa bokaholimo ba karolo e nyane ea mosebetsi, 'me ea etsa hore bokaholimo ba mosebetsi bo batalle, ho tlosa kotsi ea burr, ho ntlafatsa boemo ba sesebelisoa.'Me sandblasting e ka otla mateano a holim'a sebaka sa mosebetsi oa likhutlo tse nyenyane haholo tse chitja, e le hore mosebetsi oa matsoho o hlahe o le motle le o nepahetseng haholoanyane.

3.Ntlafatsa thepa ea mochini ea likarolo

likarolo Mechanical ka sandblasting, ka hlahisa junifomo e ntle bumpy holim'a holim'a likarolo (motheo oa mohlala), e le hore lubricant bolokoa, e le hore maemo a lubrication ntlafatsa, le ho fokotsa lerata ho ntlafatsa tšebeliso ea nako mechine.

4.Karolo ea ho qetela e khanyang

①Hloekisa bokaholimo ba lisebelisoa tse fapaneng ho etsa hore bokaholimo ba mosebetsi bo be ntle le ho feta.

②Ho etsa hore workpiece e boreleli le litlhoko tse sa bonahaleng.

③Bakeng sa mosebetsi o itseng o khethehileng, sandblasting e ka finyella ponahalo e fapaneng kapa matt ka ho rata.Tse kang tšepe e sa hloekang workpiece, lehong thepa ea ka tlung matte holim'a matte, frosted khalase holim paterone, hammoho le holim 'a lesela moriri sebetsa.

5.Ho imolla khatello ea maikutlo le ho matlafatsa holim'a metsi

Ka sandblasting holim'a workpiece ho felisa khatello ea kelello le ho eketsa matla a holim'a workpiece, tse kang liliba, likere, lisebelisoa machining le mahare a sefofane le tse ling workpiece holim'a phekolo.

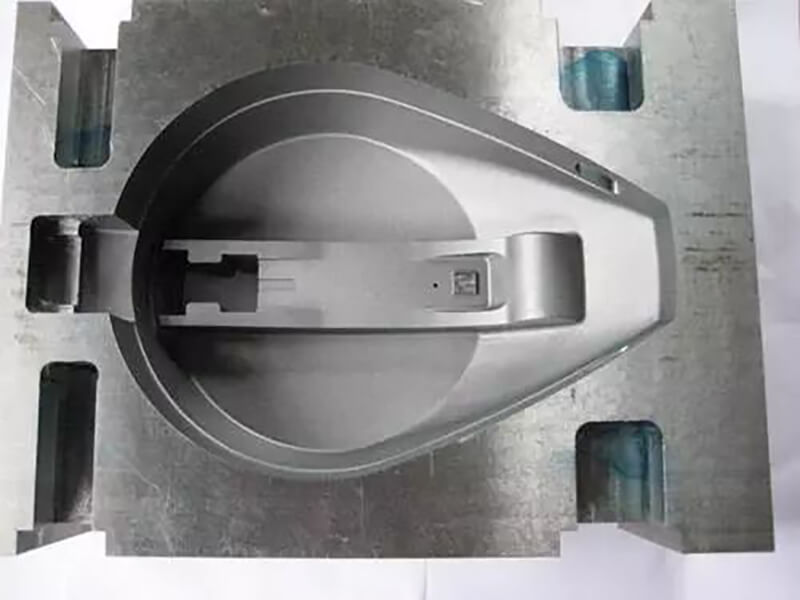

6.Ho hloekisa hlobo

Shoa holim'a argon matte holim'a kalafo, tlhahiso ea litšoantšo, hammoho le ho hloekisa shoa, ho se utloise bohloko holim'a hlobo, ho netefatsa ho nepahala ha hlobo, ho akarelletsa le aluminium alloy die-casting die, hlobo ea aluminium extrusion, hlobo ea thaere, botlolo ea khalase. hlobo, joalo-joalo.