Lihlahisoa

Synthetic Diamond Polishing Micro Powder

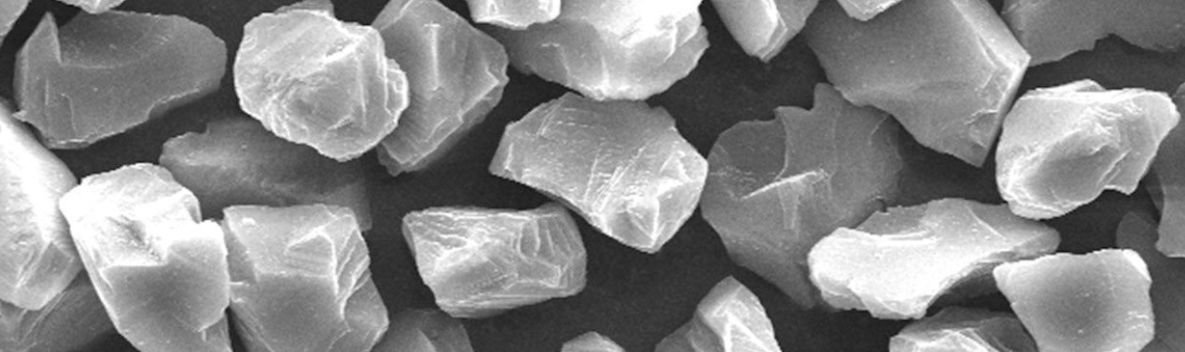

Monocrystalline Diamond phofo

Monocrystalline Diamond Powder e hlahisoa ho tsoa ho lithollo tsa maiketsetso tsa taemane tse nang le kristale e le 'ngoe ka mokhoa oa khatello ea static, e sithabetseng le ho bōptjoa ho sebelisoa mokhoa o khethehileng oa thepa e thata haholo. Likaroloana tsa eona li boloka thepa ea kristale e le 'ngoe ea daemane e le' ngoe ea kristale.

| Tlhaloso | D50 (μm) | Tlhaloso | D50 (μm) |

| 0-0.05 | 0.05 | 5-10 | 6.5 |

| 0-0.08 | 0.08 | 6-12 | 8.5 |

| 0-0.1 | 0.1 | 8-12 | 10 |

| 0-0.25 | 0.2 | 8-16 | 12 |

| 0-0.5 | 0.3 | 10-20 | 15 |

| 0-1 | 0.5 | 15-25 | 18 |

| 0.5-1.5 | 0.8 | 20-30 | 22 |

| 0-2 | 1 | 20-40 | 26 |

| 1-2 | 1.4 | 30-40 | 30 |

| 1-3 | 1.8 | 40-60 | 40 |

| 2-4 | 2.5 | 50-70 | 50 |

| 3-6 | 3.5 | 60-80 | 60 |

| 4-8 | 5 |

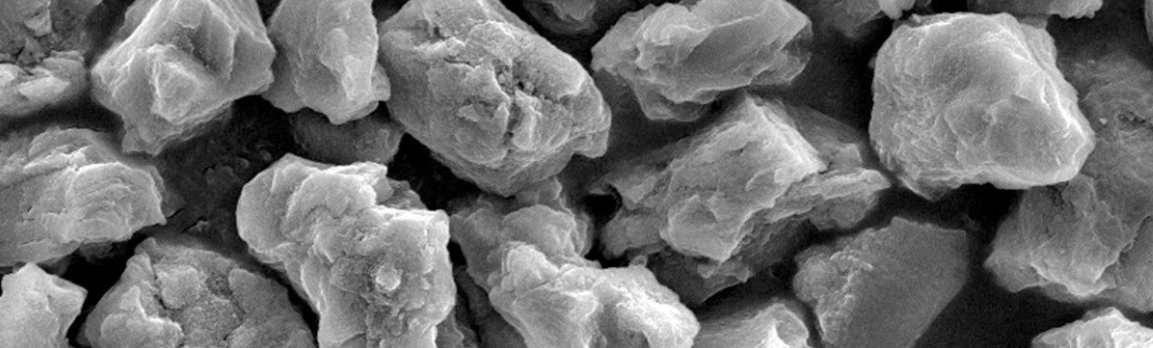

Powder ea Diamond ea Polycrystalline

Polycrystalline daemane phofo ke likaroloana tsa micron le sub-micron polycrystalline tse entsoeng ka lijo-thollo tsa daemane tse bophara ba 5 ~ 10nm tse hokahaneng ka li-bond tse sa tsitsang. Hare-hare ke isotropic mme ha e na lifofane tse phunyeletsang. E na le boima bo phahameng. Ka lebaka la thepa ea eona e ikhethang ea sebopeho, hangata e sebelisoa bakeng sa ho sila le ho bentša lisebelisoa tsa semiconductor, li-ceramics tse nepahetseng, jj.

Boholo bo fumanehang ba diamond micro powder bo ka tlase:

Litšobotsi tsa Sehlahisoa

-Oversize e tlositsoe ka botlalo

- PSD e nyane

-Bohloeki ba sefahleho bo ka fihla boemong ba ppm

-Dispersibility e ikhethang

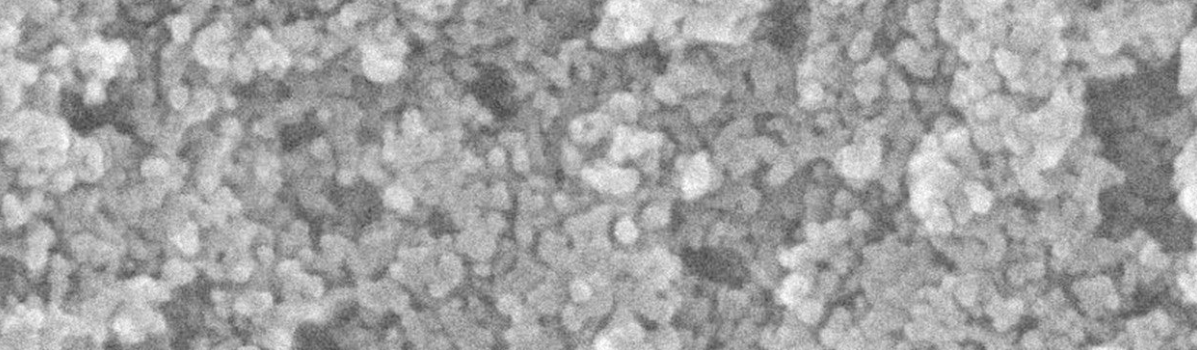

Nano Diamond phofo

Phofo ea daemane ea Nano e entsoe ka likristale tse nyane tse ka tlase ho nanometer ea 20, boemo bo ikhethileng bo hlahisang daemane e bōpehileng joaloka pherekano e nang le sehlopha se ruileng se sebetsang holimo, sebaka sa eona se ikhethileng se eketsoa ka tatellano e le 'ngoe ea boholo ha e bapisoa le daemane ea monocrystalline. Sehlahisoa sena ha se na feela boima bo babatsehang le litšobotsi tsa ho sila tsa daemane, empa hape se na le litšobotsi tse ncha tsa thepa ea nanofunctional.

| Boholo | ND50 | ND80 | ND100 | ND120 | ND150 | ND200 | ND300 | ND500 | ND800 |

| D50(nm) | 45-55 | 75-85 | 90-110 | 110-130 | 140-160 | 180-220 | 280-320 | 450-550 | 750-850 |

Litšobotsi

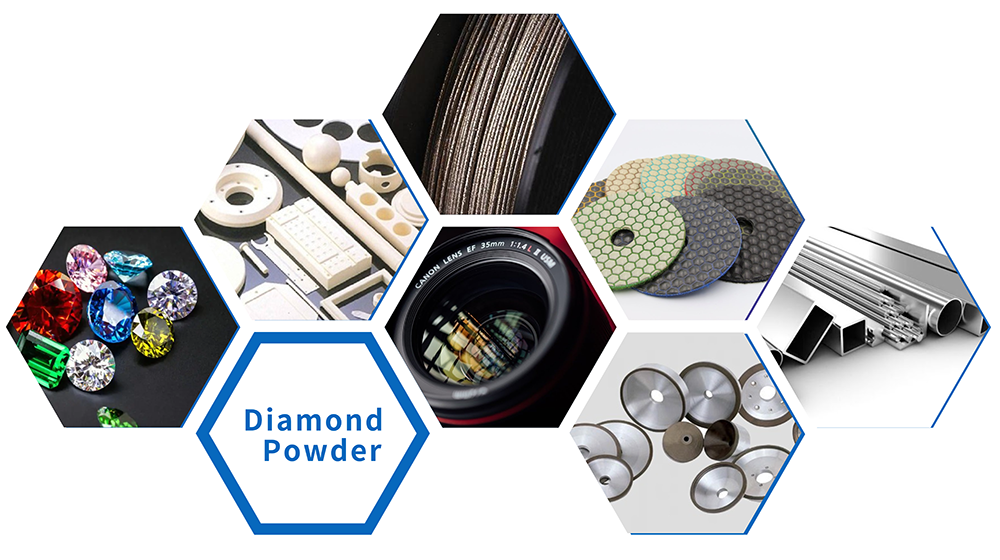

Kopo ea Powder ea Diamond ea Monocrystalline

1. E loketse lithapo tse fapa-fapaneng tsa litaemane tsa electroplated tse phahameng ka ho fetisisa, mabili a silang a daemane a electroplated, SiC crystal cutting, lithipa, li-blade tse tšesaane haholo, joalo-joalo.

2. E loketse maqephe a kopantsoeng a daemane, polycrystalline ea diamond le lihlahisoa tsa tšepe tsa tšepe, lihlahisoa tsa bond ea ceramic, lihlahisoa tsa daemane tsa electroplated, joalo-joalo.

3. E loketse lisebelisoa tsa daemane tse nang le electroplated, mabili a sila, joalo-joalo tse sebelisoang ka ho khetheha bakeng sa ho sebetsana le lisebelisoa tse thata le tse brittle.

4. E loketse bakeng sa ho sila ka mokhoa o nepahetseng le ho belisoa ha mahakoe a phahameng a holimo, lilense, lisebelisoa tsa metallographic, liphanele tsa LCD, LCD khalase, safire, maqephe a quartz, li-substrates tsa safire tsa LED, khalase ea LCD, lisebelisoa tsa ceramic, joalo-joalo.

Likopo tsa Powder Diamond ea Polycrystalline

1. Ho tšesaane le ho bentša liphaphatha tsa semiconductor, joalo ka SiC wafer le safire.

2.Ho belisoa ha sefahleho sa lisebelisoa tse sa tšoaneng tsa ceramic

3.Ho bentša holim'a lisebelisoa tsa tšepe, tse kang tšepe e sa hloekang, motsoako oa aluminium joalo-joalo.

Lisebelisoa tsa Powder ea Diamond ea Nano

1. Ho bentša hantle haholo. Bokaholimo ba lisebelisoa tse betliloeng bo ka fihla boemong ba angstrom ntle le mengwapo, e ka khotsofatsang tlhoko e matla ka ho fetesisa ea ho belisoa.

2. Nano diamond e ka sebelisoa e le li-additives tsa oli e tlotsang. Khohlano e thellang e tla fetoloa hore e be rolling friction, e ka fokotsang coefficient ea likhohlano le ho ntlafatsa haholo ts'ebetso ea likhohlano le ho lelefatsa bophelo ba ts'ebeletso.

3. Composite plating le ho fafatsa holim'a li-workpieces tse fapa-fapaneng, ho matlafatsa khanyetso ea ho apara, ho hanyetsa kutu, ho ba le tšusumetso e matla le ho thatafala ha holim'a li-workpieces.

4. Joaloka li-additives tsa rabara le li-plastiki, daemane ea nano e ka ntlafatsa haholo ho hanyetsa ha eona, ho hanyetsa ho phunyeha, thepa e tsitsitseng le ho liehisa mokhoa oa ho tsofala.

5. Ho hloeka ha daemane ea nano e phahameng e ke ke ea baka ho lahloa ha likokoana-hloko, ha ho ntse ho le joalo e ka sebelisoa haholo litabeng tsa bongaka, tsa likokoana-hloko le tsa litlolo ka lebaka la sebaka sa eona se seholo se khethehileng sa holim'a metsi, matla a adsorption a matla.

Potso ea hau

Haeba u na le lipotso.Ka kopo ikutloe u lokolohile ho ikopanya le rona.