Alumina e tšoeu e kopantsoeng e fumaneha ka mefuta e fapaneng, ho kenyelletsa le grits, lehlabathe le phofo, 'me e sebelisoa mefuteng e fapaneng ea ts'ebeliso:

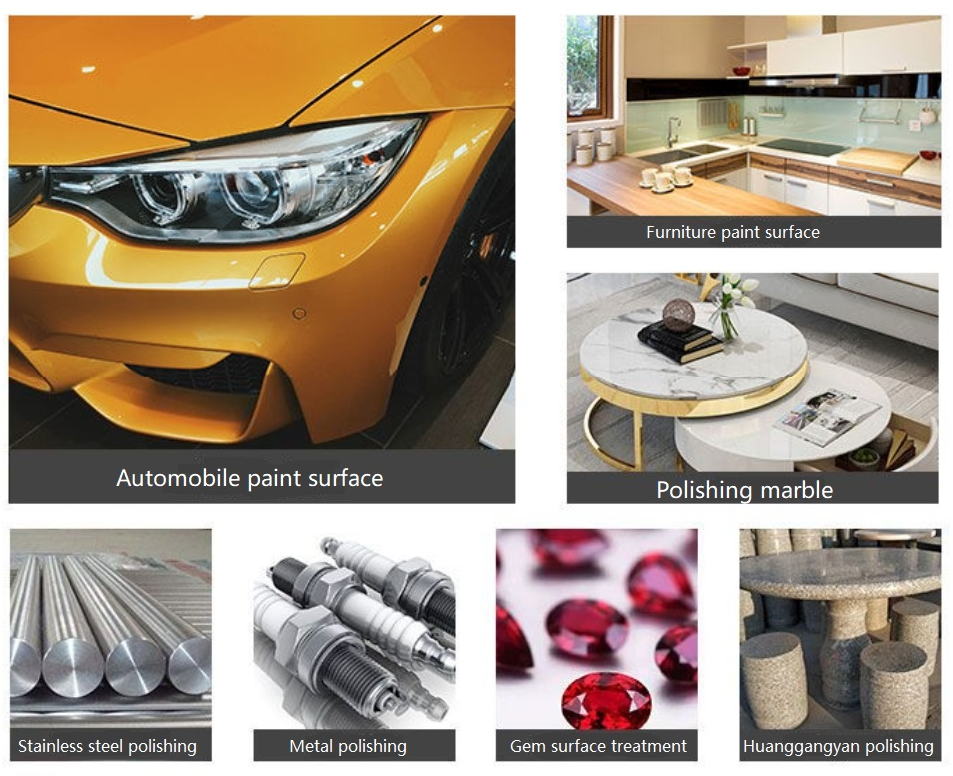

- Ho sila le ho bentša: mabili a abrasive, mabanta le discs bakeng sa ho sila ka nepo ha litšepe, lirafshoa le metsoako.

- Tokiso ea Sefahleho: litsi tsa motheo, masela a tšepe, le kaho ea likepe

- Refractories: litene tsa mollo, li-castable tse refractory, le lihlahisoa tse ling tse bōpehileng kapa tse se nang sebopeho.

- Precision Casting: liforomo tsa matsete kapa li-cores, tse hlahisang ho nepahala ha maemo a holimo, libaka tse boreleli, le boleng bo ntlafetseng ba ho lahlela.

- Abrasive Blasting: ho hloekisa holim'a metsi, ho khabisa le ho lokisa liindasteri tse kang tsa tšepe, likoloi le sefofane, tlosa mafome, pente, sekala le litšila tse ling ntle le ho baka tšenyo.

- Li-superabrasives: lithulusi tse tlanngoeng kapa tse koetsoeng, litšepe tse lebelo le holimo, litšepe tsa lisebelisoa le lirafshoa.

- Ceramics le Lithaele