Lihlahisoa

Platelet Calcined Alumina Powder

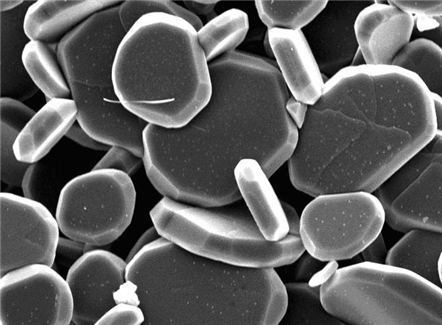

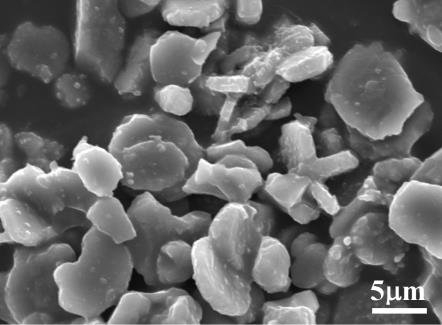

Plate Calcined Alumina polishing powder e entsoe ka phofo ea alumina ea boleng bo holimo e le thepa e tala, 'me e sebetsoa ka mokhoa o khethehileng oa tlhahiso. Sebopeho sa kristale sa phofo e entsoeng ka alumina e benyang e na le hexagonal flat joaloka sebopeho sa tabular, kahoo e bitsoa Platelet Alumina kapa Tabular Alumina.

Platelet Alumina ke phofo ea boleng bo holimo ea alumina ea mofuta oa abrasive, e nang le kristale e bōpehileng joaloka poleiti ea Al2O3 e nang le bohloeki bo fetang 99.0%. E na le litšobotsi tse ntle tse thibelang mocheso hammoho le ho se sebetse hantle ka lik'hemik'hale, 'me ha e chesoe ke li-acids kapa alkaline. Ha kabo ea boholo ba likaroloana tsa Platelet Alumina e laoloa ka thata, e ka hlahisa bokaholimo bo botle haholo, e fanang ka ts'ebetso e ntle ka ho fetesisa joalo ka e senya. Ka mefuta e mengata ea lisebelisoa, Platelet Alumina ke phofo e hlabang e khonang ho etsa mesebetsi e mengata.

Tabular alumina phofo

Tabular alumina phofo

Litlhaloso tse Tloaelehileng tsa Boholo ba Karolo

| Karoloana | Kabo ea Karolo (µm) | |||

| Boholo ba karoloana | Boholo ba likaroloana | Boholo ba likaroloana | Boholo ba likaroloana | |

| 45 | 82.9 | 53.4± 3.2 | 34.9± 2.3 | 22.8± 1.8 |

| 40 | 77.8 | 41.8± 2.8 | 29.7± 2.0 | 19.0± 1.0 |

| 35 | 64.0 | 37.6± 2.2 | 25.5± 1.7 | 16.0± 1.0 |

| 30 | 50.8 | 30.2± 2.1 | 20.8± 1.5 | 14.5± 1.1 |

| 25 | 40.3 | 26.3± 1.9 | 17.4± 1.3 | 10.4± 0.8 |

| 20 | 32.0 | 22.5± 1.6 | 14.2± 1.1 | 9.00±0.80 |

| 15 | 25.4 | 16.0± 1.2 | 10.2± 0.8 | 6.30±0,50 |

| 12 | 20.2 | 12.8± 1.0 | 8.20±0.60 | 4.90±0,40 |

| 9 | <16.0 | 9.70±0.80 | 6.40±0,50 | 3.60±0,30 |

| 5 | 12.7 | 7.20±0,60 | 4.70±0,40 | 2.80±0,25 |

| 3 | 10.1 | 5.20±0,40 | 3.10±0,30 | 1.80±0.30 |

Maemo a Boleng

| Mofuta oa sehlahisoa | Matla a Khoheli a khethehileng | ||||

| Al2O3 | SiO2 | Fe2O3 | Na2O | ||

| 3µm-45µm | hoo e ka bang 3.90 | =99.0 | <0.20 | <0.10 | <1.00

|

Melemo ea Alumina Power

1. Bapisa le phofo e 'ngoe ea tabular, phofo ea alumina ea tabular e na le thepa e ntle ea ho kopanya. Joalo ka ntlha e phahameng ea ho qhibiliha, ho thatafala ho matla, matla a phahameng a mochini, ho hanyetsa ho apara hantle, ho hanyetsa lik'hemik'hale, ho hanyetsa oxidation le ho hanyetsa mocheso joalo-joalo.

2. Sebopeho sa letlapa le sephara se etsa hore khohlano e be kholoanyane, e ntlafatsa lebelo la ho sila le katleho, sena se ka fokotsa palo ea mechine ea ho sila, mosebetsi le nako ea ho sila.

3. Sebopeho sa letlapa le bataletseng se etsa hore ntho e se ke ea e-ba bonolo ho e senya, tekanyo ea lihlahisoa tse tšoanelehang e ka eketsa 10% -15%. Mohlala, sekhahla sa semiconductor silicon wafer se tšoanelehang se ka fihla ho 96% kapa ho feta.

4. E na le liphello tse peli tsa nano le li-powders tse nyenyane, mosebetsi oa holim'a metsi o leka-lekaneng, ha o khone ho kopana ka katleho le lihlopha tse ling tse sebetsang, empa hape ha ho bonolo ho kopanya le ho tsamaisa ho hasana ho atlehang.

5. E na le sekhomaretsi se setle, phello ea bohlokoa ea tšireletso le bokhoni ba ho bonahatsa leseli.

6. Tabular alumina phofo e batla e le pepeneneng, ha e na 'mala,' me e na le sebaka se bataletseng le se boreleli. Likristale tse khabisitsoeng hantle ke li-hexagon tse tloaelehileng.

7. Tabular alumina phofo e ka etsoa phofo e ntle haholo ea ho bentša.

1. Indasteri ea lisebelisoa tsa elektronike: ho sila le ho bentša liphaephe tsa semiconductor monocrystalline silicon, likristale tsa quartz quartz, li-semiconductors tse kopantsoeng (crystalline gallium, phosphating nano).

2. Indasteri ea khalase: ho sila le ho sebetsa ha kristale, khalase ea quartz, skrine ea khetla ea khalase ea kinescope, khalase ea optical, substrate ea khalase ea metsi (LCD) ea khalase, le kristale ea quartz.

3. Indasteri ea ho roala: liaparo tse khethehileng le li-fillers bakeng sa ho fafatsa ka plasma.

4. Indasteri ea tšepe le ea ceramic: lisebelisoa tse nepahetseng tsa ceramic, lisebelisoa tse tala tsa sintered ceramic, liphahlo tse phahameng tsa mocheso o phahameng, joalo-joalo.

Potso ea hau

Haeba u na le lipotso.Ka kopo ikutloe u lokolohile ho ikopanya le rona.