Kenyelletso le ts'ebeliso ea li-abrasives tsa daemane

Taemane ke ntho e nang le boima bo phahameng ka ho fetisisa tlhahong. E na le boima bo phahameng haholo, conductivity ea mocheso le ho hanyetsa ho roala, kahoo e sebelisoa haholo indastering ea abrasive. Ka nts'etsopele ea theknoloji ea indasteri,li-abrasives tsa daemaneli ntlafalitse ho tloha litaemane tse tloaelehileng tsa tlhaho ho ea ho litaemane tse sa tšoaneng tsa maiketsetso le lisebelisoa tse sebetsang tse kopantsoeng, ho fetoha karolo ea bohlokoa ea tšimo ea lisebelisoa tse thata haholo, 'me li sebelisoa haholo liindastering tse ngata tse nepahetseng tse kang ho sebetsa ka mechine, lisebelisoa tsa elektronike, optics le matla a macha.

Ⅰ. Kenyelletso ea mantlha ea li-abrasives tsa daemane

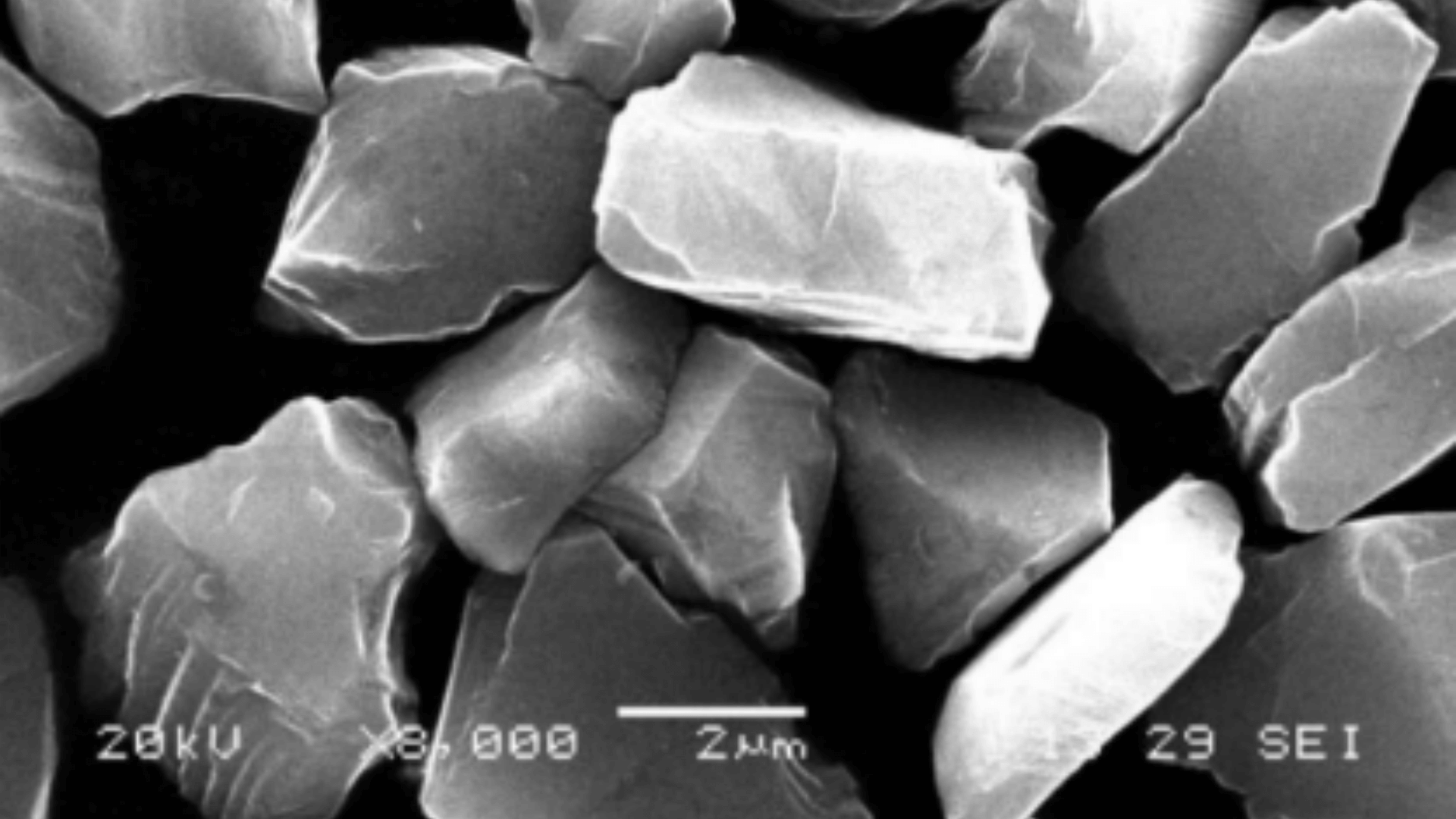

Li-abrasives tsa daemane lilintho tse entsoeng ka phofo kapa granular e entsoeng ka ho silakanya, ho lekola, le tlhoekiso ea litaemane tsa tlhaho kapa litaemane tsa maiketsetso. Bongata ba eona ba Mohs bo fihla boemong ba 10, e leng eona e tsebahalang ka ho fetisisa ea abrasive. Ha ho bapisoa le li-abrasives tse tloaelehileng tse kang aluminium oxide le silicon carbide, li-abrasives tsa daemane li na le bokhoni bo phahameng ba ho itšeha le ho hanyetsa ho apara, 'me li ka sila le ho bentša lisebelisoa tse thata haholo ka katleho e phahameng le tšenyo e tlaase.

Li-abrasive tsa daemane haholo-holo li kenyelletsa mefuta e latelang:

Diamond micropowder: Boholo ba likaroloana bo tloha ho mashome a li-micron ho ea ho nanometers, tse loketseng mekhoa e fapaneng ea ho belisa ka mokhoa o nepahetseng.

Lebili la ho sila taemane/ Hlooho e silang: e sebedisoang bakeng sa ho sila le ho bopa dintho tse thata.

Diamond saw blade / drill bit: e sebelisetsoang ho seha le ho cheka thepa e kang lejoe, lirafshoa, likhalase, joalo-joalo.

Mokelikeli o silang oa daemane / pente e benyang: e sebelisoa haholo ts'ebetsong e nepahetseng ka ho fetesisa ho tsa elektronike, li-optics, hlobo le liindasteri tse ling.

Lisebelisoa tsa daemane tse kopantsoeng (PCD/PCBN): e kopanya daemane le tšepe kapa matrix ea ceramic ho etsa lisebelisoa tse kopaneng tsa lisebelisoa tse thata le ho hanyetsa ho roala.

Ⅱ. Libaka tsa kopo ea li-abrasives tsa daemane

1. Ho sebetsa ka mechine

Li-abrasives tsa daemane li sebelisoa haholo ha ho etsoa le ho sila ha thepa e thata haholo, e kang carbide e entsoeng ka samente, li-ceramics, silicon carbide, khalase, ferrite, joalo-joalo Ho sebelisa mabili a sila a daemane bakeng sa ho sebetsa ho ke ke ha ntlafatsa haholo ts'ebetso ea ts'ebetso le boleng ba holim'a metsi, empa hape le ho lelefatsa bophelo ba sesebelisoa le ho fokotsa maqhubu a phetoho ea sesebelisoa. E loketse ka ho khetheha bakeng sa mekhoa ea tlhahiso e entsoeng ka bongata, e ikemetseng e phahameng ka ho fetisisa.

2. Liindasteri tsa elektroniki le tsa semiconductor

Nakong ea ts'ebetso ea lisebelisoa tse kang li-wafers tsa silicon, li-sapphire substrates, li-silicon carbide chips, khalase ea optoelectronic, joalo-joalo, lisaha tsa terata ea daemane, maro a silang le li-paste tsa polishing ke lisebelisoa tsa bohlokoa. Li-abrasives tsa daemane li ka fihlella botlaaseng ba submicron kapa esita le nanometer-level flatness le roughness. Li sebelisoa haholo lihokelong tsa bohlokoa joalo ka chip dicing, wafer grinding, le pholishe ea photomask. Ke ntlha ea bohlokoa ho netefatsa ts'ebetso e phahameng le lihlahisoa tse phahameng tsa lihlahisoa tsa elektronike.

3. Ts'ebetso ea optical

Phofo ea daemane e sebelisoa haholo ho bentša likhalase tsa optical, lifensetere tsa laser, lilense tsa safire le likarolo tse ling. Matla a eona a babatsehang a ho itšeha le botsitso ba lik'hemik'hale li ka ntlafatsa ka katleho boleng ba ho sebetsa ka seiponeng le ho finyella boemo bo holimo ba Ra bo ka tlaase ho 10nm. Ke lisebelisoa tsa bohlokoa bakeng sa ho fihlella libaka tse boreleli le ho fetisa khanya e phahameng.

4. Kaho le ts'ebetso ea majoe

Li-blades tsa daemane, likotoana tsa boro, lithapo tse sehang joalo-joalo li sebelisoa haholo ha ho etsoa thepa ea kaho e kang granite, marble, le konkreite. Ha ho bapisoa le lisebelisoa tsa setso, lisebelisoa tsa daemane li phahametse lebelo la ho itšeha, bophelo ba ts'ebeletso, le boleng ba ho itšeha, 'me li loketse ka ho khetheha bakeng sa ts'ebetso e sebetsang ea thepa ea kaho e matla le e phahameng.

5. Matla a macha le sepakapaka

Ka nts'etsopele ea theknoloji e ncha ea matla, tlhokahalo ea li-abrasives tsa daemane ha ho etsoa likotoana tsa lithium battery pole, li-diaphragm tsa ceramic, likarolo tsa koloi ea motlakase, joalo-joalo e ntse e hōla ka potlako. Lefapheng la aerospace, lisebelisoa tsa daemane li sebelisoa bakeng sa machining a nepahetseng a likarolo tse chesang tsa enjene, likarolo tsa meralo tse kopaneng, joalo-joalo, tse ntlafatsang ho ts'epahala le ho tšoarella ha lihlahisoa.

III. Qetello

Li-abrasives tsa daemane, e le lisebelisoa tsa bohlokoa bakeng sa tlhahiso ea indasteri ea sejoale-joale, li ntse li amoheloa ke maemo a holimo a holimo a machining ka lebaka la thepa ea ona e metle ea 'mele le ts'ebeliso e pharaletseng. Nakong e tlang, ka tsoelo-pele e tsoelang pele ea mahlale a thepa le theknoloji ea tlhahiso, li-abrasives tsa daemane li tla tsoela pele ho ntshetsa pele ka tsela e hloekisitsoeng haholoanyane, e bohlale le e se nang botsoalle ho tikoloho, ho thusa indasteri ea tlhahiso e phahameng ho ea boemong bo phahameng.