Tlhahiso e Ekelitsoeng le Tlhahiso e Hlahisang: Puisano mabapi le Tšebeliso ea Molds Behind Precision Machining.

Ho etsoa ha indasteri ea sejoale-joale ho hlahisitse litlhoko tse phahameng tsa ho nepahala, ho sebetsa hantle le tokoloho ea moralo. Ntle le mahlale a setso a ho etsa thepa (joalo ka ho sila, ho sila, joalo-joalo),tlhahiso ea tlatsetso (khatiso ea 3D)theknoloji e boetse e hlaha ka potlako 'me e fetoha mokhoa oa bohlokoa oa ho hlahisa mekhoa e mecha. Ka bobeli li na le melemo ea tsona 'me li sebelisoa haholo masimong a likoloi, sefofane, lisebelisoa tsa bongaka le tlhahiso ea mechini. Mekhoeng ena e 'meli ea tlhahiso, karolo ea hlobo e bohlokoa haholo' me e amana ka kotloloho le boleng ba ts'ebetso le katleho ea tlhahiso.

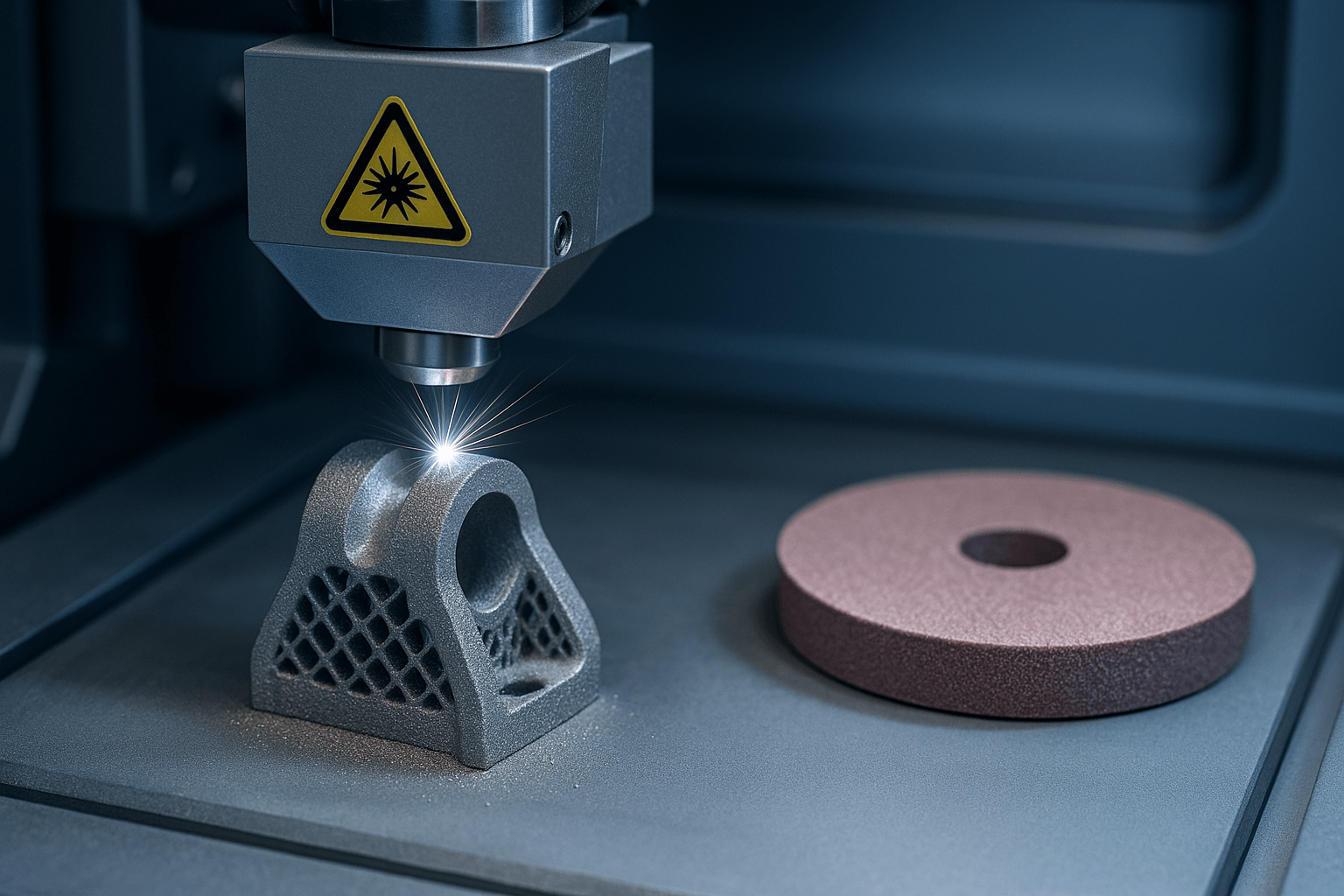

Kenyelletso ea Theknoloji ea Additive Manufacturing le Kopo ea Mold

Tlhahiso e eketsang, eo hape e tsejoang e le khatiso ea 3D, ke ts'ebetso ea ho aha likarolo ka ho bokella thepa ka lera. Litheknoloji tse tloaelehileng tsa tlhahiso ea li-additive li kenyelletsa selective laser sintering (SLS), selective laser melting (SLM), fused deposition modeling (FDM) le stereolithography (SLA). Theknoloji ea mofuta ona e tsebahala ka tokoloho ea eona e phahameng haholo ea moralo. E ka etsa likarolo tse nang le libopeho tse rarahaneng le li-cavities tse ka hare kapa mekhoa ea marang-rang, e nang le tšebeliso e phahameng ea thepa le ho fokotsa litšila tsa thepa haholo. Ho etsa li-additive ho loketse ka ho khetheha bakeng sa prototyping e potlakileng, tlhahiso ea li-batch tse nyane le ho iketsetsa motho ka mong, 'me e sebelisoa haholo sebakeng sa lifofane, likoloi, lisebelisoa tsa bongaka le tlhahiso ea hlobo. Melemo ea eona e boetse e kenyelletsa ho khutsufatsa potoloho ea nts'etsopele, ho khothaletsa moralo o mocha le ho phethahala ha litharollo tse fapaneng.

Leha tlhahiso ea tlatsetso e ka theha meaho e rarahaneng ka kotloloho, bokaholimo ba likarolo tse hatisitsoeng hangata bo mahoashe, bo na le mela e meholo le mefokolo e menyane, 'me mochini o latelang oa hlokahala ho fihlela litlhoko tsa boholo le boleng ba bokaholimo. Ka nako ena, li-abrasives tse sebetsang hantle li fetoha lisebelisoa tsa bohlokoa. Li-abrasives tse kangmabili a ho sila, mabanta a lehlabathe, mabili a phunyeletsang le mabili a benyang a sebelisoa haholo bakeng sa ho senya, ho fokotsa holim'a metsi le ho qeta likarolo tse ling tsa tlhahiso ea lihlahisoa ho etsa bonnete ba hore lihlahisoa li fihla ho nepahala ha boemo ba indasteri le botle bo botle. Haholo-holo litabeng tsa aerospace le tsa bongaka, litlhoko tse phahameng tsa boleng bo holimo le ts'ebetso li tsamaisitse li-abrasives hore li tsoele pele ho hlahisa lisebelisoa tse phahameng tsa ts'ebetso le tse phahameng tsa ho apara ho finyella litlhoko tse khethehileng tsa tlhahiso ea li-additive post-processing.

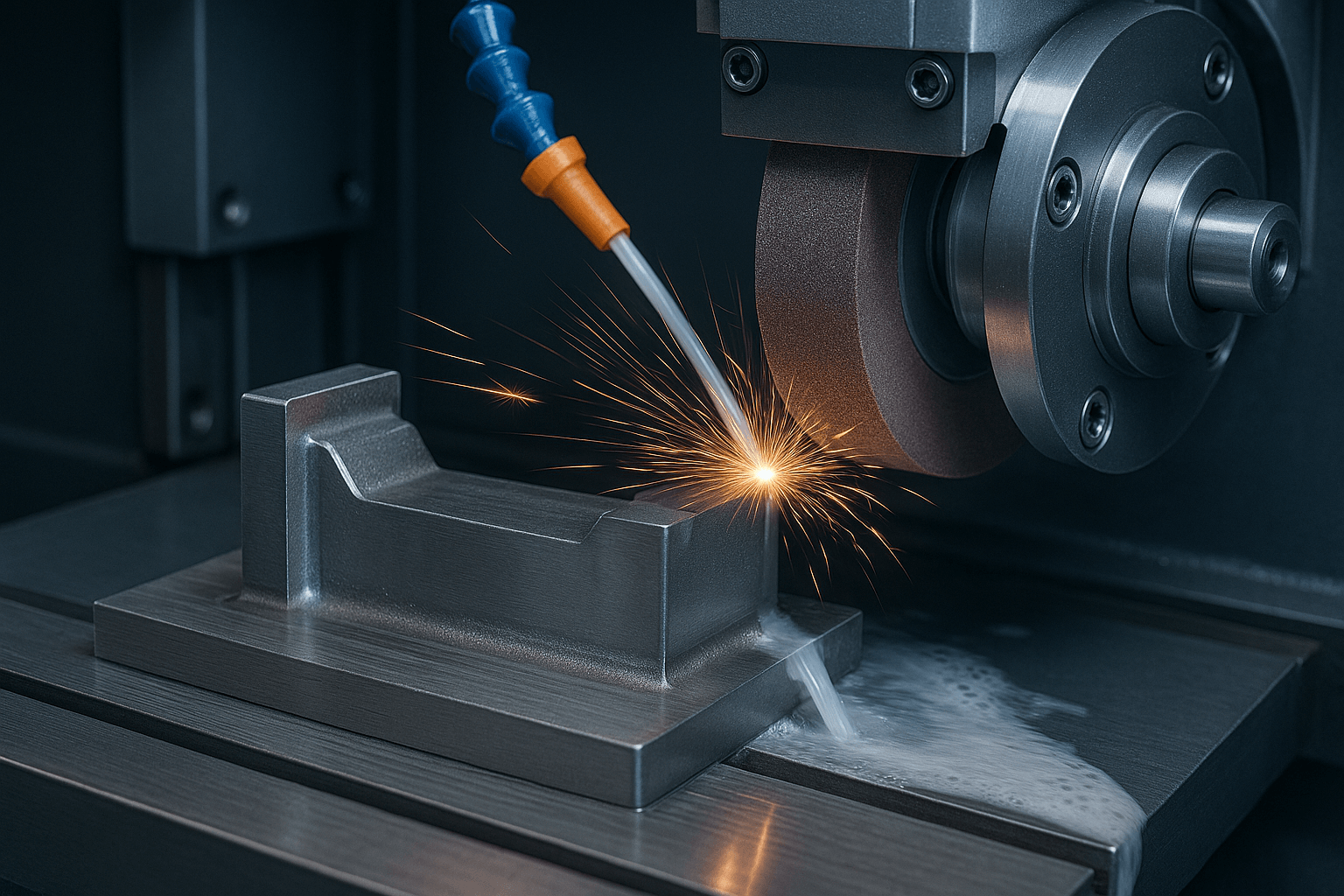

Kenyelletso ho thekenoloji ea tlhahiso ea subtractive le ts'ebeliso ea abrasive

Tlhahiso e fokolangke ho tlosa thepa e feteletseng ka ho seha, ho sila, ho sila le mekhoa e meng ea ho sebetsana le workpiece hore e be sebopeho se reriloeng esale pele. Theknoloji ena e hōlile 'me e loketse tlhahiso ea bongata, haholo-holo e ntle ho netefatsa litekanyo tse phahameng tse nepahetseng le boleng bo botle ba bokaholimo. Mekhoa e tloaelehileng e kenyelletsa ho sila ha CNC, ho reteleha, ho sila, ho seha terata, mochine oa ho ntša motlakase (EDM), ho itšeha ka laser le ho khaola jete ea metsi. Ho etsa lintho tse fokolang ho bapala karolo ea mantlha tlhahisong ea likoloi, sebaka sa sefofane, tlhahiso ea mechini le lisebelisoa tsa bongaka. E ka sebetsana ka katleho le tšepe, tšepe e entsoeng ka tšepe, li-alloys tsa aluminium le lisebelisoa tse kopantsoeng ho finyella litlhoko tse tiileng tsa indasteri bakeng sa ho tšoarella le ho sebetsa.

Li-Abrasives li bapala karolo ea mantlha le ea bohlokoa tlhahisong e fokolang, haholo ts'ebetsong ea ho sila. Mefuta e fapaneng ea mabili a sila (joalo ka mabili a sila a ceramic, mabili a silang a resin) le lisebelisoa tsa ho bentša li sebelisoa haholo bakeng sa machining a thata, ho qeta le ho bentša holim'a metsi ho latela litlhoko tsa ts'ebetso ho netefatsa hore likarolo li fihlella ho nepahala ho phahameng le boleng ba bokaholimo ba seipone. Ts'ebetso ea abrasive e ama ka kotloloho ts'ebetso ea ts'ebetso le boleng ba sehlahisoa, e susumetsang boqapi bo tsoelang pele ba lisebelisoa le meaho ea abrasive ho fihlela litlhoko tsa ts'ebetso ea thepa e thata haholo le lijeometri tse rarahaneng.

Joalo ka borokho ba bohlokoa lipakeng tsa tse peli, li-abrasives li ts'ehetsa khokahano e se nang moeli ho tloha ho tlhahiso ea tlatsetso ho isa tlhahisong e tlase. Ka ts'ebeliso e ntseng e eketseha ea lisebelisoa tse kopantsoeng le lisebelisoa tse thata haholo, ntlafatso ea theknoloji ea abrasive e fetohile sehokelo sa bohlokoa ho netefatsa boleng ba tlhahiso. E le karabelo ho mathata a holim'a metsi a ikhethileng a kenyelletsoeng le litlhoko tse phahameng tse nepahetseng tsa tlhahiso e fokolang, lipatlisiso le nts'etsopele ea hlobo e ntse e tsoela pele ho fihlela boima bo phahameng, sebopeho se betere le bophelo bo bolelele, ho khothaletsa bohlale le katleho ea ketane eohle ea tlhahiso.