Lihlahisoa

Metal abrasive Steel Grit Blast Media

TS'EPE LEHLAKO

Mecha ea litaba e mabifi e sebelisoa ho qhomisa le ho hlobolisa tšepe le litšepe tsa motheo. Steel Grit e hlahisa ka mokhoa o ts'oanelang lirapeng tse thata bakeng sa mamarelo a betere ho kenyelletsa lipente, epoxy, enamel le rabara. Lisebelisoa li kenyelletsa ho lokisa koloi ea terene, ho tlosoa ha marokho a benyang, a qhomisang, likarolo tsa tšepe le lisebelisoa tsa indasteri ea forging.

| Lihlahisoa | Tšepe Grit | |

| Sebopeho sa Lik'hemik'hale | CR | 1.0-1.5% |

| C | 1.0-1.5% | |

| Si | 0.4-1.2% | |

| Mn | 0.6-1.2% | |

| S | ≤0.05% | |

| P | ≤0.05% | |

| Ho thatafala | Ho thunngoa ka tšepe | GP 41-50HRC;GL 50-55HRC;GH 63-68HRC |

| Botenya | Ho thunngoa ka tšepe | 7.6g/cm3 |

| Sebopeho sa Micro | Sebopeho sa Martensite | |

| Ponahalo | Spherical Hollow particles<5% Crack particle <3% | |

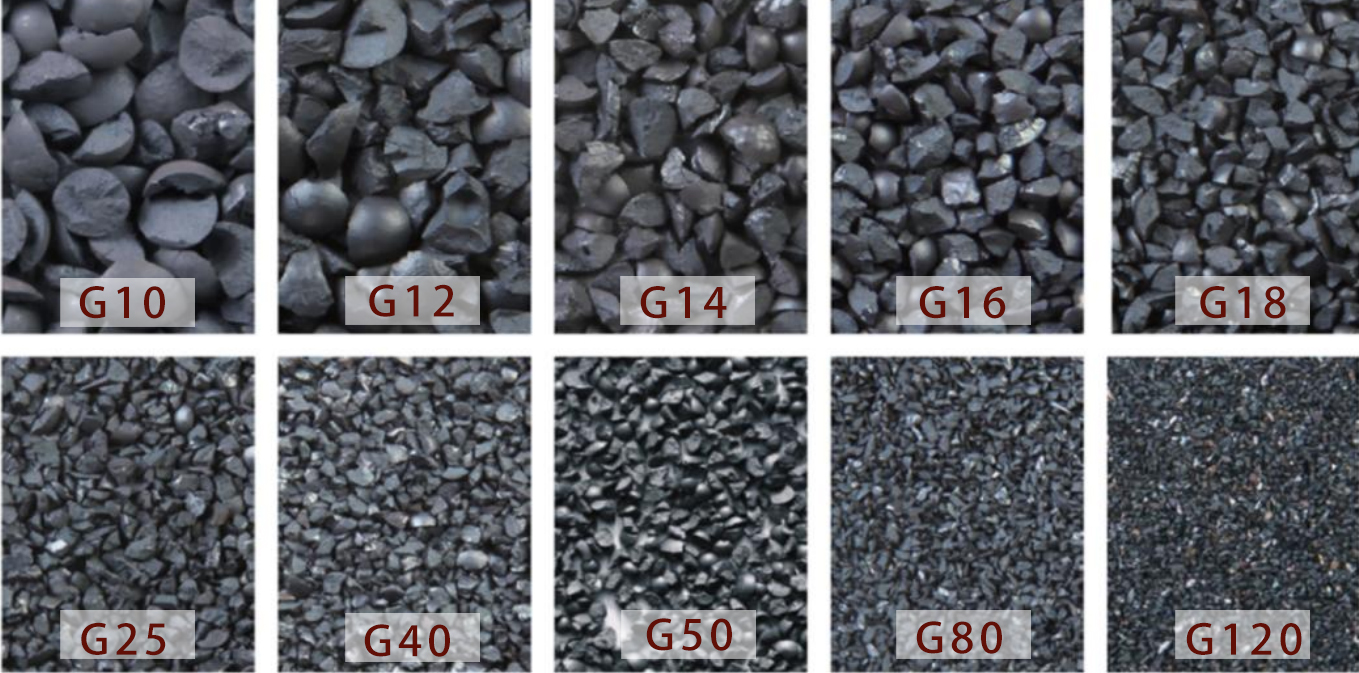

| Mofuta | G120,G80,G50,G40,G25,G18,G16,G14,G12,G10 | |

| Diameter | 0.2mm,0.3mm,0.5mm,0.7mm,1.0mm,1.2mm,1.4mm,1.6mm,2.0mm,2.5mm | |

Sesebelisoa sa Grit ea tšepe

1.Tlhahiso ea Bokaholimo: Litšepe tsa tšepe li sebelisoa haholo bakeng sa ho lokisa holim'a metsi pele li sebelisa litlolo, lipente kapa li-adhesives. Ka katleho ba tlosa mafome, sekala, liphahlo tsa khale, le litšila tse tsoang holim'a tšepe, ho etsa bonnete ba ho khomarela hantle thepa e latelang.

2.Rust le Corrosion Remotion: Li-grits tsa tšepe li sebelisetsoa ho tlosa mafome a boima, ho senya, le leloala ho tloha holim'a tšepe, haholo-holo liindastering tse kang ho haha likepe, tlhokomelo ea likepe, le lisebelisoa tsa tšepe tsa mohaho.

3.Ho Lokisetsa ho Welding: Pele ho ts'ebetso ea welding kapa mekhoa e meng ea ho kopanya, li-grits tsa tšepe li ka sebelisoa ho hloekisa le ho lokisa libaka, ho netefatsa hore ho na le li-weld tse matla le tse hloekileng.

4.Concrete le Stone Surface Tokiso: Lithako tsa tšepe li ka sebelisoa ho hloekisa le ho lokisa libaka tsa konkreite le majoe, tse kang merero ea tsosoloso, moo ho tlosoa liphahlo tsa khale, litšila kapa litšila ho hlokahalang.

5.Shot Peening: Le hoja lithunya tsa tšepe li atisa ho sebelisoa bakeng sa ho thunngoa, li-grits tsa tšepe li ka boela tsa sebelisoa bakeng sa ts'ebetso ena. Ho phunya ho kenyelletsa ho phunya bokaholimo ka likaroloana tse hlabang ho baka khatello ea maikutlo, e leng ho matlafatsang matla a thepa le ho hanyetsa mokhathala.

6.Deburring le Deflashing: Li-grits tsa tšepe li sebelisetsoa ho tlosa li-burrs, likarolo tse bohale, le lisebelisoa tse feteletseng ho tloha likarolong tsa tšepe, haholo-holo mekhoeng ea tlhahiso moo ho hlokahalang ho nepahala le ho boreleli.

Likopo tsa 7.Foundry: Li-grits tsa tšepe li sebelisoa litsing tsa ho hloekisa le ho lokisa libaka tsa ho lahlela, ho tlosa hlobo le ho tlosoa ha motheo, le phekolo e akaretsang ea holim'a tšepe. 8.Surface Profileing: Li-grits tsa tšepe li sebelisoa ho etsa litlaleho tse khethehileng tsa holim'a metsi, haholo-holo liindastering tse kang tsa kaho le tsa likepe. Litlaleho tsena li ntlafatsa ho khomarela liphahlo le ho fana ka ts'ebetso e ntle bakeng sa libaka tse khahlanong le ho thella.

9. Ho Seha Lejoe la Lejoe: Liindastering tsa kaho le liemahale, li-grits tsa tšepe li sebelisetsoa ho seha le ho khabisa majoe le lisebelisoa tse ling tse thata, ho etsa meralo le mekhoa e rarahaneng.

10.Indasteri ea Oli le Khase: Litšepe tsa tšepe li sebelisoa bakeng sa ho lokisa bokaholimo indastering ea oli le khase, joalo ka ho hloekisa liphaephe, litanka le lisebelisoa tse ling.

11.Indasteri ea Likoloi: Litšepe tsa tšepe li ka sebelisoa bakeng sa ho hlobolisa pente le liphahlo tse tsoang likarolong tsa likoloi, ho lokisa libaka bakeng sa ho nchafatsoa kapa ho tsosolosoa.

Ho bohlokoa ho hlokomela hore khetho ea boholo bo nepahetseng ba grit ea tšepe, ho thatafala le lintlha tse ling ho ipapisitse le ts'ebeliso e khethehileng le pheletso e batloang ea bokaholimo. Lintho tse hlabang tsa grits tsa tšepe li li etsa lisebelisoa tsa bohlokoa bakeng sa mesebetsi e hlokang ho tlosoa ha thepa e matla le ho fetoloa ha bokaholimo.

Potso ea hau

Haeba u na le lipotso.Ka kopo ikutloe u lokolohile ho ikopanya le rona.