Lihlahisoa

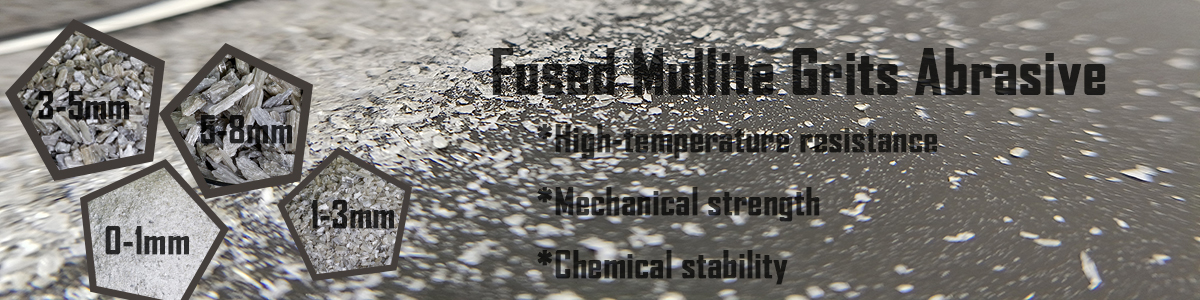

Litlhaloso tse ikhethileng 1-0mm 3-1mm 5-3mm 8-5mm Blasting Media Grains e Fused Mullite 79% Molten Mullite Grits

Fused Mullite Tlhaloso

Mullite e kopantsoenge na lebotsitso bo botle ba mocheso, matla a phahameng, katoloso e tlase ea mocheso, le khanyetso e ntle ea lik'hemik'hale.E tsebahala ka thepa ea eona e ikhethang ea refractory, e etsa hore e tšoanelehe bakeng sa lits'ebetso tse fapaneng tsa mocheso o phahameng. Litšebeliso tse ling tse tloaelehileng tsa mullite tse kopantsoeng li kenyelletsa:Lisebelisoa tsa Refractory,Indasteri ea Ceramic,Indasteri ea Foundry,Li-abrasives, joalo-joalo.

Tlhaloso ea Fused Mullite

| Karolo ea boholo ba lihlahisoa | |

| Lehlabathe la karolo | 1-0mm; 3-1 limilimithara; 5-3 limilimithara; 8-5 limilimithara |

| Brand | XINLI Abrasive |

| Lisebelisoa | Refractory, castable, blasting, grinding, lapping , holim'a metsi, polishing |

| Sebopeho sa Lik'hemik'hale tsa Sehlahisoa | |

| Al2O3% ≥ | 74-79% |

| SiO2 | 20-25% |

| Fe2O3 | ≤0.1% |

| MgO | / |

| Sebopeho sa Sehlahisoa | |

| Linear Katoloso Coefficient (1/°C) | -6.0×10-6 |

| Boima ba 'Nete | 3.10 g/cm3min |

| Khalase Phase | 5 %Boholo |

| Porosity | 6% |

| Melting Point | 1830°C |

| * Lihlahisoa tse ikhethileng: Re ka fana ka lihlahisoa tse hlophisitsoeng tsa mullite tse hlophisitsoeng ka mefuta e fapaneng le litlhaloso tsa lik'hemik'hale ho latela litlhoko tsa bareki. | |

Likarolo tsa Fused Mullite

Mullite e kopantsoengke thepa ea bohlokoa liindastering mooho hanyetsa mocheso o phahameng, matla a mochine, le botsitso ba lik'hemik'hale ke tsa bohlokoa. Ho feto-fetoha ha eona le ho ts'epahala ho etsa hore e be khetho e ratoang bakeng sa lits'ebetso tse batloang haholo makaleng a refractory, ceramic le foundry.

- Lisebelisoa tsa Refractory: Fused Mullite e sebelisoa haholo tlhahiso ea litene tse refractory, li-castable, le lihlahisoa tse ling tse refractory. Ho hanyetsana ha eona ho phahameng, ho hanyetsa mocheso oa mocheso, le mocheso o tlaase oa mocheso o etsa hore e be e loketseng bakeng sa libopi tsa masela, libopi le lisebelisoa tse ling tsa indasteri tse nang le mocheso o phahameng.

- Indasteri ea Ceramic: Fused Mullite e sebelisoa ha ho etsoa lirafshoa tse tsoetseng pele, tse kang crucibles, thermocouple protection tubes, le sebōpi sa thepa ea ka tlung. Botsitso ba eona bo botle ba mocheso le ho hanyetsa tlhaselo ea lik'hemik'hale ho etsa hore e be thepa e ratoang bakeng sa lisebelisoa tsa ceramic.

- Indasteri ea Foundry: Fused Mullite e sebelisoa indastering ea lihlahisoa e le lisebelisoa bakeng sa hlobo le li-cores ka lebaka la matla a eona a mocheso o phahameng le botsitso ba sebopeho.

- Li-Abrasives: Fused Mullite e ka sebetsoa hore e be lijo-thollo tse abrasive tse sebelisoang ho sila mabili, lisebelisoa tsa ho itšeha, le lisebelisoa tse ling tse hobohang. Ho thatafala ha eona le ho tiea ha eona ho tlatsetsa katlehong ea eona e le ntho e senyang.

Potso ea hau

Haeba u na le lipotso.Ka kopo ikutloe u lokolohile ho ikopanya le rona.